Airbound: Delivering Abundance

On one-rupee delivery; moving atoms like bits; and a Bangalore startup's quest to engineer the world's most efficient aircraft

Hey folks👋

A warm welcome to the 1040 new Tigerfeathers subscribers who’ve joined since our last piece, about ‘Everyday Auras’ and the economics of India’s fragrance boom.

This week is all about Auradynamics Aerodynamics. If you have a (very) long flight on the horizon and you’re looking to learn about “India’s most audacious hardware company”, you’ve come to the right place👇

This edition of Tigerfeathers is presented in partnership with…Airbound

“This isn’t about where the industry is at, and this isn’t about what the market is demanding. This is about exploring the limits of possibility and building tech at the very edge. That’s where the future will meet us.”

Airbound is an aerospace company based in Bangalore that wants to make logistics ‘invisible, instant, and affordable’.

To achieve that, their team has been obsessed with building ‘the best aircraft physically possible’. That may sound like classic startup-speak, but in practice they’ve gone to absurd lengths to create what is today the most efficient autonomous vehicle (i.e. drone) that’s ever existed.

Their idea is to use these hilariously-lightweight-but-sturdy drones as part of an aerial delivery fleet, potentially bringing down the emissions and costs associated with last-mile delivery to (near) zero.

The company envisions this technology as something akin to the Internet for the physical world, fundamentally reimagining how we move atoms from Point A to Point B.

They see it decongesting our cities and erasing the distance penalty for people in every postcode in India, as well as reshaping our relationship with the items that make up our daily lives (RIP to our refrigerators).

Last mile delivery is their first milestone (starting with the transport of blood samples and critical medical supplies in the outskirts of Bangalore), but Airbound wants to eventually scale its technology to move a significant chunk of the world’s freight, and then its people - quickly, cheaply and safely through the sky over the coming decades.

The company’s grand ambitions bely the fact that it began as a modest side-project by its founder Naman Pushp when he was still a 15-year-old high school student in mid-2020, bored at home during the pandemic.

Naman and I met for the first time at the start of this year, and in April, we got to chatting about officially working together to tell the story of Airbound for Tigerfeathers, to coincide with the closure of their $8.65 million seed funding round, announced earlier this week.

It’s meant that for the last five months, I’ve spent several hours with the Airbound team to understand what they’re building, why it matters, and why I should have paid more attention in Physics. If you’re looking for a reason to dive into today’s piece, here are three:

Airbound is that rare Indian startup that - *if* it succeeds - will change how the world works. They are not competing for market share as much as they’re attempting to add a new layer to the infrastructure of global transport.

Everyone at the company is hyper aware that any version of a successful outcome hinges solely on whether their aircraft can do what they say it can do, which means this is at its heart a story of novel engineering - a case study on employing first-principles thinking to invent technology that doesn’t yet exist.

To increase the odds of a successful outcome, Naman doesn’t just want to create a breakthrough aircraft, he wants to create a culture that makes breakthroughs inevitable. It’s why Airbound is fixated on becoming a magnet for India’s most cracked engineers - a place to tackle the hairiest technological problems without the burden of accepted convention. (If you’re a talented engineer languishing somewhere that barely scratches the surface of your abilities, Airbound is hiring)

As always - *nervous laughter* - this is not a short piece. In fact, not only is this a very long story, but it’s also a deeply technical one, that takes plenty of scenic detours through topics like drones, aviation, aerodynamics, composites, and fat turtles.

For reasons that will become apparent, and to do justice to both the high stakes and long odds of Airbound’s success, this story is one that we felt merited the time and investment to tell properly. It will broadly cover the origin of the company; their technical breakthroughs and ambition; the use case they’re solving for; and what the world will look like if they’re successful.

We hope you enjoy reading as much as we enjoyed writing. With that, let’s get to it.

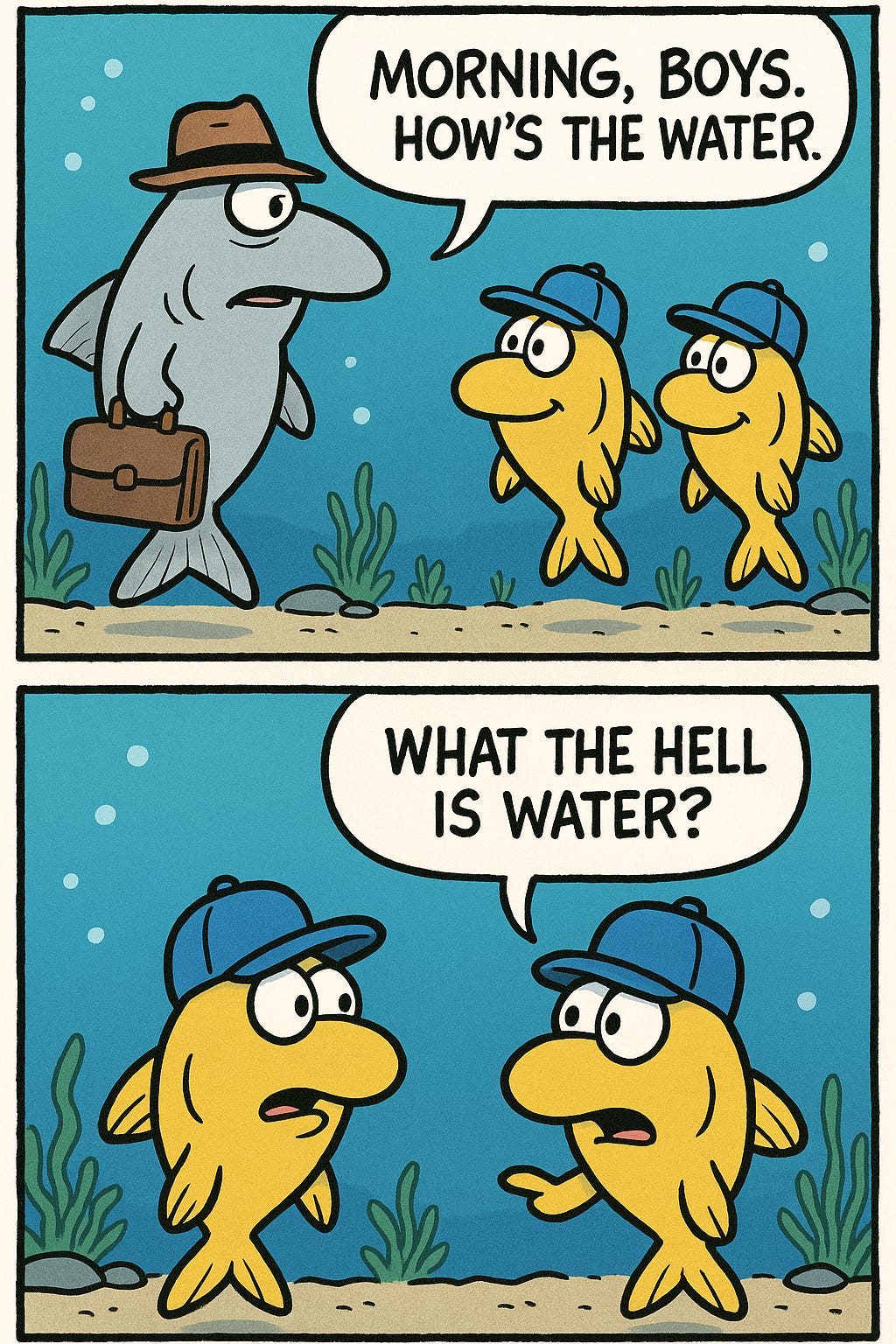

What is a loonshot?

A loonshot is something nobody has dared to do before. A goal so ambitious that you don’t even know if its possible. Landing on the moon was a loonshot, building reusable rockets was a loonshot, fusion is a loonshot. More commonly referred to as moonshots, I prefer the term loonshot because it highlights the necessary stupidity a bit better.

What’s a mini-loonshot?

Well it’s just like a loonshot, but smaller. A mini-loonshot is building something extremely out of distribution, but at nowhere near the scale of a real loonshot. They maintain the spirit of ‘something only a loon would build’.

The reason nobody has built a loonshot before is because it’s too hard. Nobody builds mini-loonshots because there’s no fucking reason to.

- via an unpublished blogpost on Naman’s Substack (circa 2022)

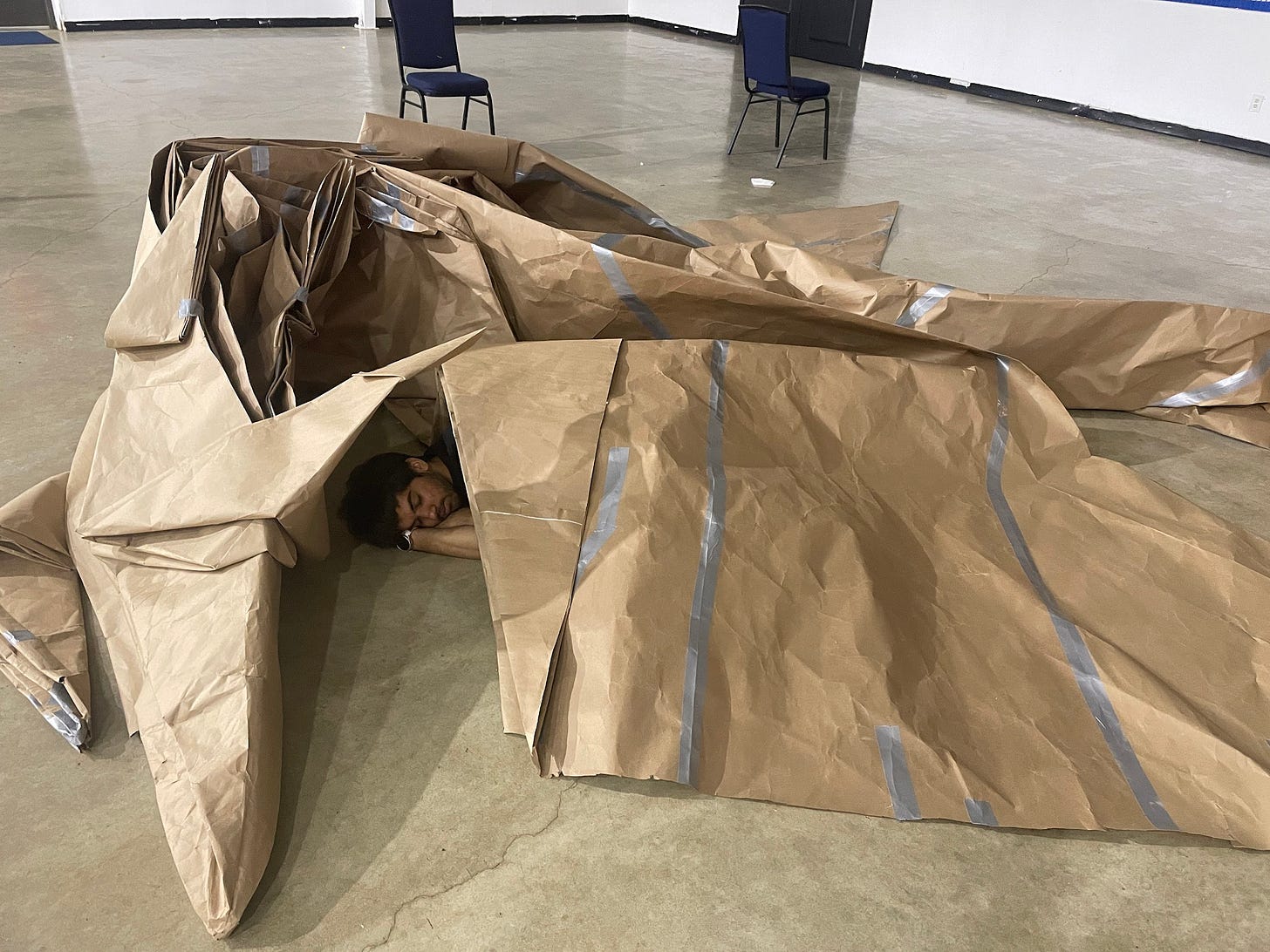

The current Guinness World Record for the largest origami dragon ever made was set in August 2020 by Paul Frasco and Shrikant Iyer, two professional origamists based in the United States. It was 12 feet 8.75 inches long, 6 feet 6.5 inches high, and 3 feet 11.5 inches wide. It took two days and 50 folds to construct, and was the culmination of a decade-long quest to push the boundaries of large-scale paper sculpture.

It is also currently mired in controversy (sort of).

The real, unofficial record for the world’s largest origami dragon was set by a trio of teenagers a couple of years later in Cambridge (UK) at what was essentially a summer camp for mathematically gifted high schoolers from around the world. The group included the founder of Airbound, who had by then gotten used to balancing his fledgling drone project along with his regular school commitments. Alongside his two campmates, the trio had managed to fold a piece of paper the size of a basketball court into an imposing rendition of a sleeping firedrake.

Without a roadmap to follow, the uncrowned record-holders reckoned with otherwise trivial tasks that became grizzly when dealing with the enhanced scale of their task. Like figuring out how to fold a sheet of paper that was six times their height; or how to stop the wind from crumpling paper that perpetually threatened to tear under the weight of its own mass.

All of this tinkering went apparently unrewarded. Their efforts would be left off the pages of (Guinness-branded) history because they had to vacate the premises only a few hours after their project was completed, leaving only a scant gathering of administrators as the only other living witnesses to their achievement. Naman would attempt to break the record again on his own a few weeks later, getting 80% of the way there on his second attempt.

As to why anyone would put themselves through the thankless 30-hour task of building a giant origami dragon twice - an exercise that came with no tangible outcome, no real scope for future CV embellishment, no hope for street cred from cynical high schoolers, and “no value to society” - we return to Naman’s blogpost from which the opening quotes to this piece have been extracted, appropriately titled ‘The World’s Largest Origami Dragon And Why You Should Build Cool Shit’:

“Building a giant paper dragon is not, in fact, a loonshot (shocker). But it does bear striking resemblance to one, a mini-loonshot, if you will.

The key similarity between mini-loonshots and real loonshots is that they’re both extremely out-of-distribution experiences. Just like how you can’t predict the challenges you’ll face while developing a novel aircraft, you can’t predict the challenges you’ll face while attempting a 3-part collapse of a sheet of paper 6 times as tall as you. Solving these challenges isn’t something you can find through extensive research or study, rather it is a test of your ability to find creative solutions to problems with limited resources.

This is the hardest part about any loonshot, how do you prepare for the unknowable? It’s a skill. A skill you can only develop by solving unsolved problems. Again, and again, and again. There’s no pattern, no reproducible trick, because if there was, it wouldn’t be a loonshot anymore. But after a point, you learn, and get better at dealing with unknown unknowns.

Building a true loonshot project is hard, takes years, and has a very low chance of success. But if it succeeds, the payoff is huge and you can change the world. You’re not going to change the world with a mini-loonshot, but you can change your life. Things that make a task ‘cool’, ‘crazy’, or ‘fun’, also make it significantly more meaningful. And if the cost is just a couple of weeks lost instead of a couple of years, that seems quite worthwhile to me.

You should definitely build a loonshot, if you can. But if not, go out and build cool shit because…well, why not? Maybe it’ll be the start of something really big.”

To quote so liberally from someone else’s blogpost (one the author himself describes as cringe) in the opening sections of one’s own essay might seem like the pinnacle of editorial sloth, like cobbling together a bunch of Youtube clips to serve as the opening scene for your movie. Even so, I think those paragraphs represent a pretty solid introduction to Naman Pushp. Although they’ve been written in service of the challenge of building a never-been-done-before dragon, they may as well be outlining the principles that yielded a never-been-done-before drone.

As it turned out, in the same summer of 2020, as the Guinness World Records team was unjustly crowning a team of pretenders as origami-dragon-luminaries, Naman was embarking on another mini-loonshot. This project, as he presciently wrote, was indeed the start of something really big.

1. Origins

Naman was born in Mumbai, but his early childhood followed the rhythms of his parents’ banking careers. After a brief stint in Hyderabad and a longer stopover in Malaysia (spanning his elementary years), his family returned to India where he finished his schooling at the Dhirubhai Ambani International School in Mumbai.

“Malaysia was actually a great counterbalance to India,” he recalls. “School there has this collaborative environment. You don’t get gold stars for doing well in class. They reward behaviour and effort more than raw academic performance, which is a contrast to the zero-sum, scarcity mindset of Indian education. I had classmates who would tell me to keep my correct answers to myself if the teacher asked for them, as if we needed to protect our IP in the 8th grade! It helped that I was more interested in understanding fundamentals than getting good grades, though it probably didn’t hurt to shift to a more competitive environment as I got older.”

The one constant across continents was his fascination with robotics. It started in fifth grade in Malaysia, and deepened back in India when he began working with proper materials, equipment and software as part of various school competitions - chief amongst them the World Robot Olympiad (WRO) and FIRST Robotics Competition (FRC). Despite being a “hardcore computer science kid” throughout his school life, it was hardware that had captured his heart and curiosity by the 10th grade.

“To me what’s exciting about hardware is that you really can do anything,” Naman says. “You’re not limited by what can run on a laptop, you’re only limited by physics. Sure, I loved software too. I loved scratch programming. I made a bunch of computer games, zombie shooters, things like that. But software is more abstract. There’s something intuitive about working with your hands that makes it so satisfying. That grind-y aspect of spending hours just to drill a few holes in a metal box perfectly, the fact that even just doing basic alignment of components is so hard, it’s addictive. Plus robotics is a mix of so many different cool things. I knew that’s where I wanted to plant my flag.”

He had begun to work on independent robotics projects outside of school by the 9th grade. But it was the summer after his 10th grade Board exams - the summer of 2020 - that cemented his transition from curious high-schooler to zealous engineer.

2. 2020

I would imagine that for most kids that had just finished a milestone set of exams who suddenly had their summer break coincide with a pandemic-induced stay-at-home mandate, that period would represent a historic opportunity to do nothing.

“I did a lot of that too,” Naman says. “I used to be an introvert, so lockdown suited me just fine. I enjoyed the free time. But eventually the idea of rewatching Suits for the fifth time didn’t seem so appealing anymore, so I decided to do something more useful.”

Instead of baking banana bread or trading JPEGs like a normal person in 2020/21, Naman’s lockdown montage looked a little different. “I took the opportunity to level up. I started doing these online courses and certifications for things like Fusion 360 [product design and manufacturing software] and Ansys [engineering simulation software] and a few others. Eventually I got bored of that too. I didn’t want to just do some empty CV-padding. I wanted to put this knowledge to good use.”

The pandemic was fortuitously an ideal opportunity for a homebound engineer to do just that. Over the course of 2020, much of the scientific world was putting their heads together and nationalities aside to solve the most vexing problems posed by the virus. Various communities had emerged to corral funding and design-input for emergency medical solutions. One of these communities was called Helpful Engineering, which welcomed contributors of all shapes and sizes.

“I started getting involved in all these different projects, to design PAPR respirators and things like that,” says Naman. “I got to interact with amazing founders and scientists and all these experienced engineers from around the world. Everyone was super helpful and encouraging, and it kind of gave me the confidence that I could build something worthwhile too.”

In July 2020, Helpful Engineering launched a worldwide hackathon to solicit software and hardware ideas to combat the spread of the virus. Submissions included plans for intelligent masks, 3D printed ventilators, patient data processing models, home testing kits, etc. Naman threw his name in the hat, attempting to tackle the problem statement of ‘contactless delivery’. He wanted to explore how last mile logistics systems could be kept intact in a time of social distancing and a prevailing fear of interpersonal proximity. It led him down a rabbit hole to see if anyone in the world had made any headway on that front, particularly if any company had succeeded in removing humans from the delivery equation.

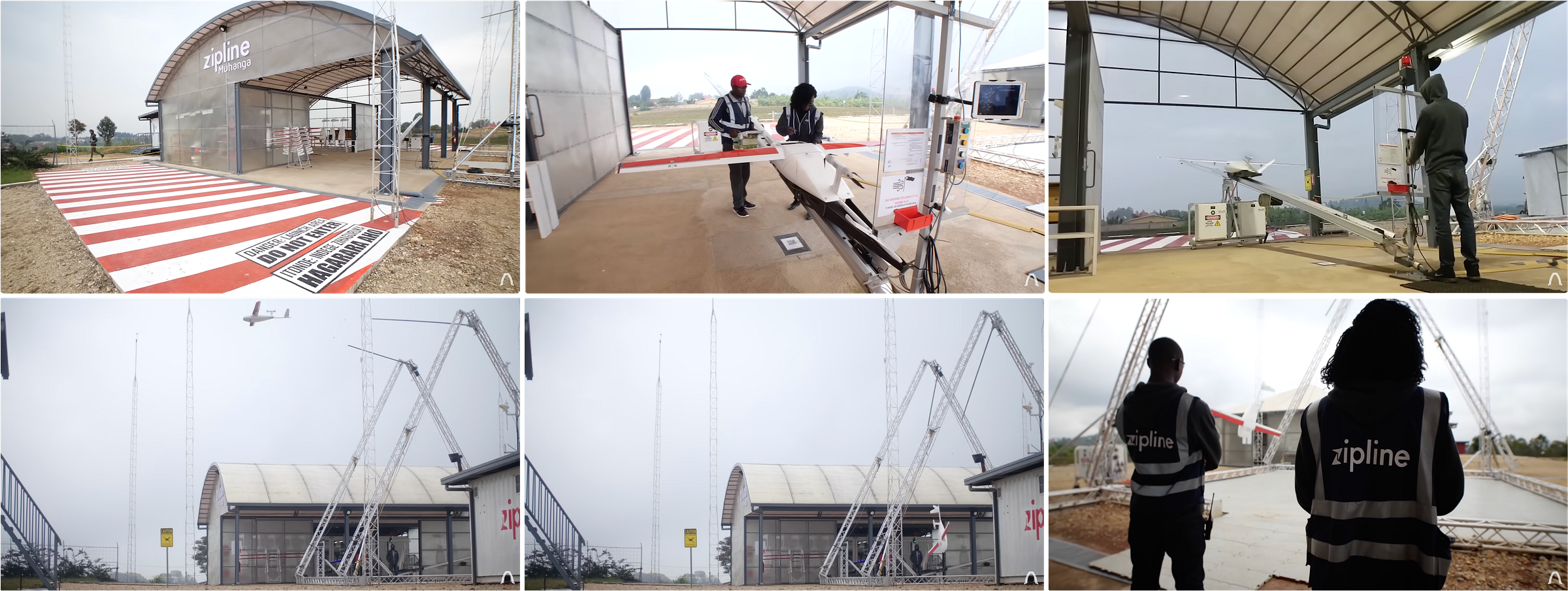

“That research eventually led me to Zipline. And that research eventually led me to drones.”

3. 12 Years / 60 Minutes

The next big thing will start out looking like a toy - Chris Dixon (2010)

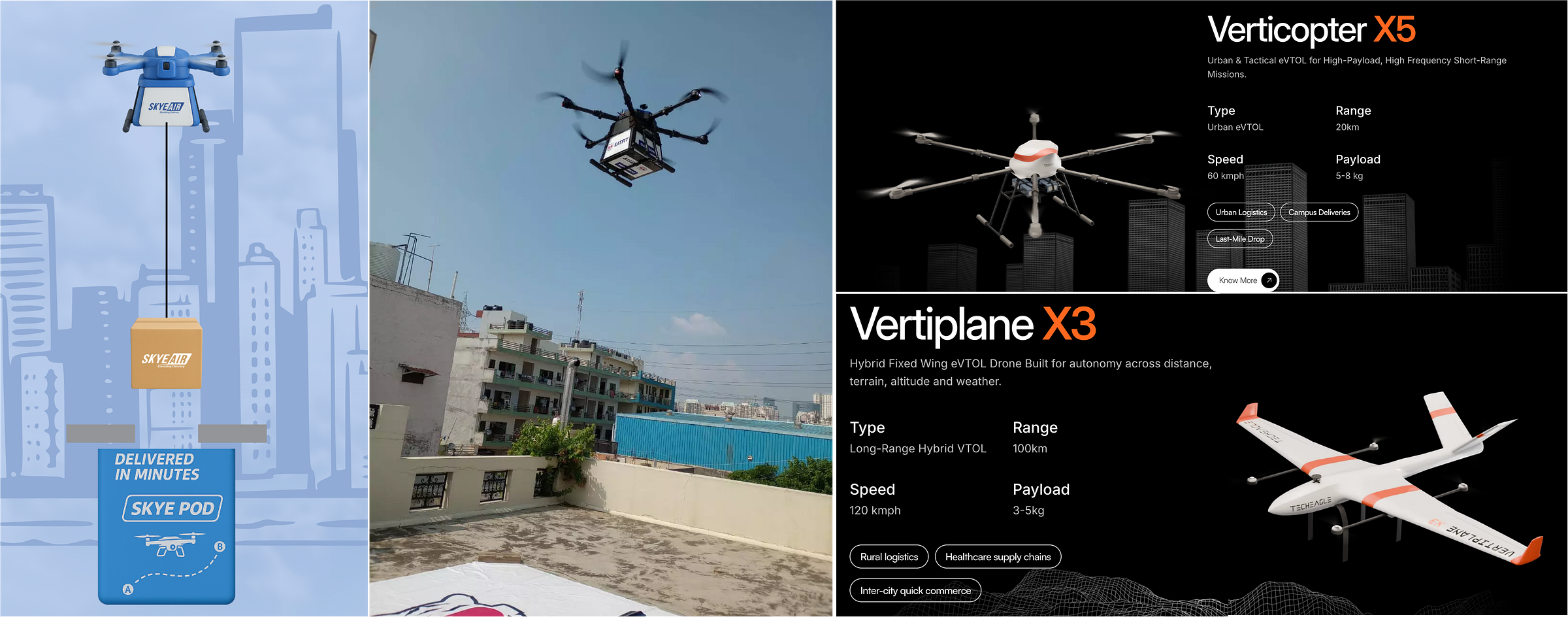

I’ll bet that for most of you reading this, when you think of drones, the image that pops into your head is this thing:

For most people, I assume that drones sit in a scarcely visited corner of your brain somewhere on the continuum between novelty and nuisance. Your association with a drone in real life is likely either as the toy your tech-enthusiast cousin brought back from their summer holiday abroad (that’s currently gathering dust in a cupboard somewhere), or it’s the device responsible for ruining that sweet moment between the bride and groom at the wedding you went to last December (courtesy of the most unholy whirring noise that has ever been set upon human ears). I feel you.

But that’s on the consumer front.

When it comes to the industrial side of things, there’s little doubt that ‘drones’ - i.e. flying vehicles that operate either autonomously or without a human pilot on board - have begun to make a tangible impact on our world. These aerial robots feature prominently in areas like mapping, agricultural monitoring, crop spraying, warehouse automation, power line inspection, search and rescue operations, defence, border security and maritime patrol etc.

Each of those areas is undoubtedly important to the smooth functioning of our world, but mostly sit outside the rumble of our daily routines. On the consumer side, while you can argue that aerial photography is a legitimate use case (for hobbyists and filmmakers alike), it wouldn’t be controversial to suggest that drones have yet to meaningfully change how the vast majority of people go about their daily lives.

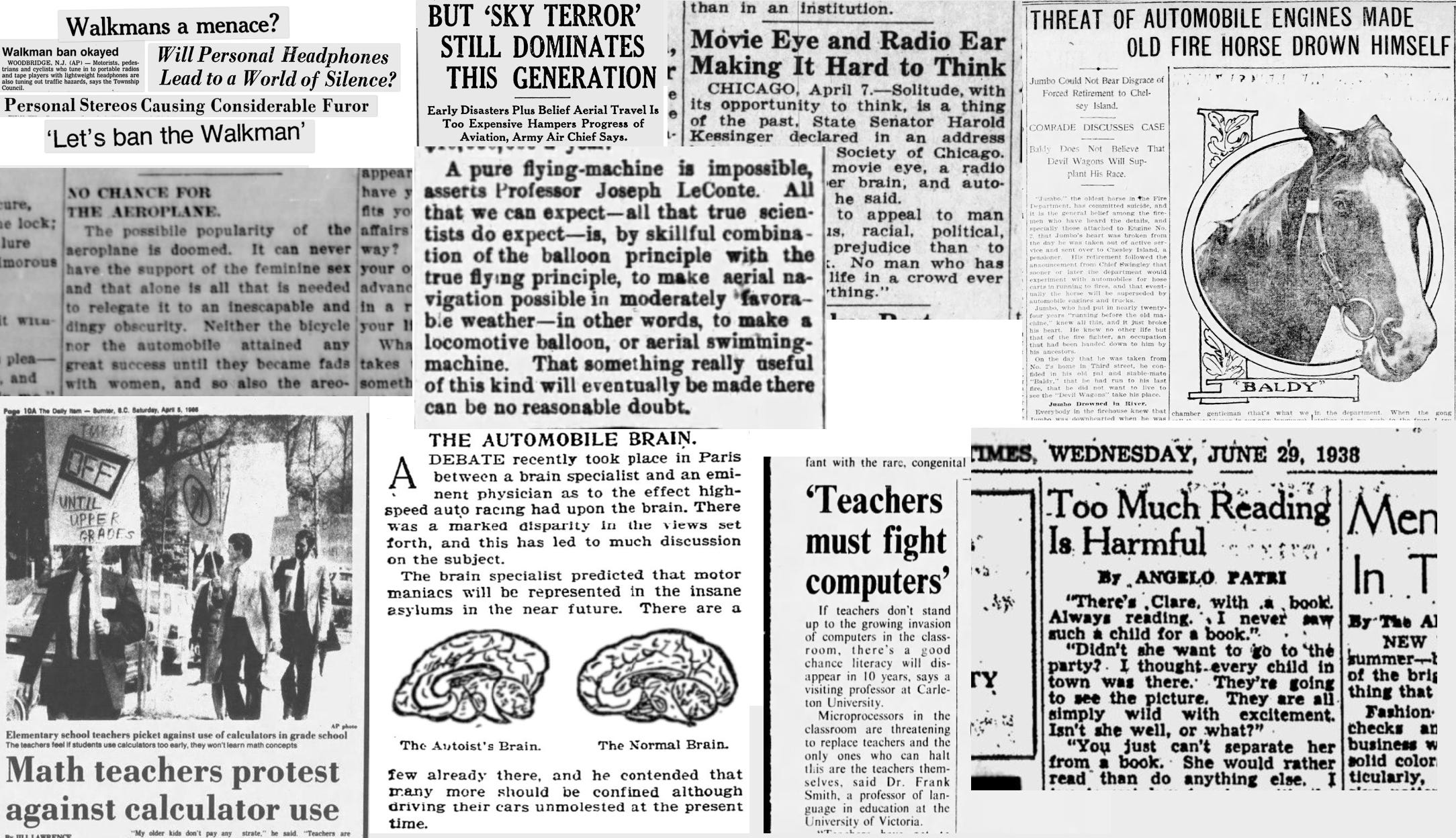

That assertion would be unremarkable, were it not for the bombastic prognostications made about the future prospects of consumer drone technology in the early the 2010s, specifically by one of the high priests (maybe the Highest Priest?) of consumer tech.

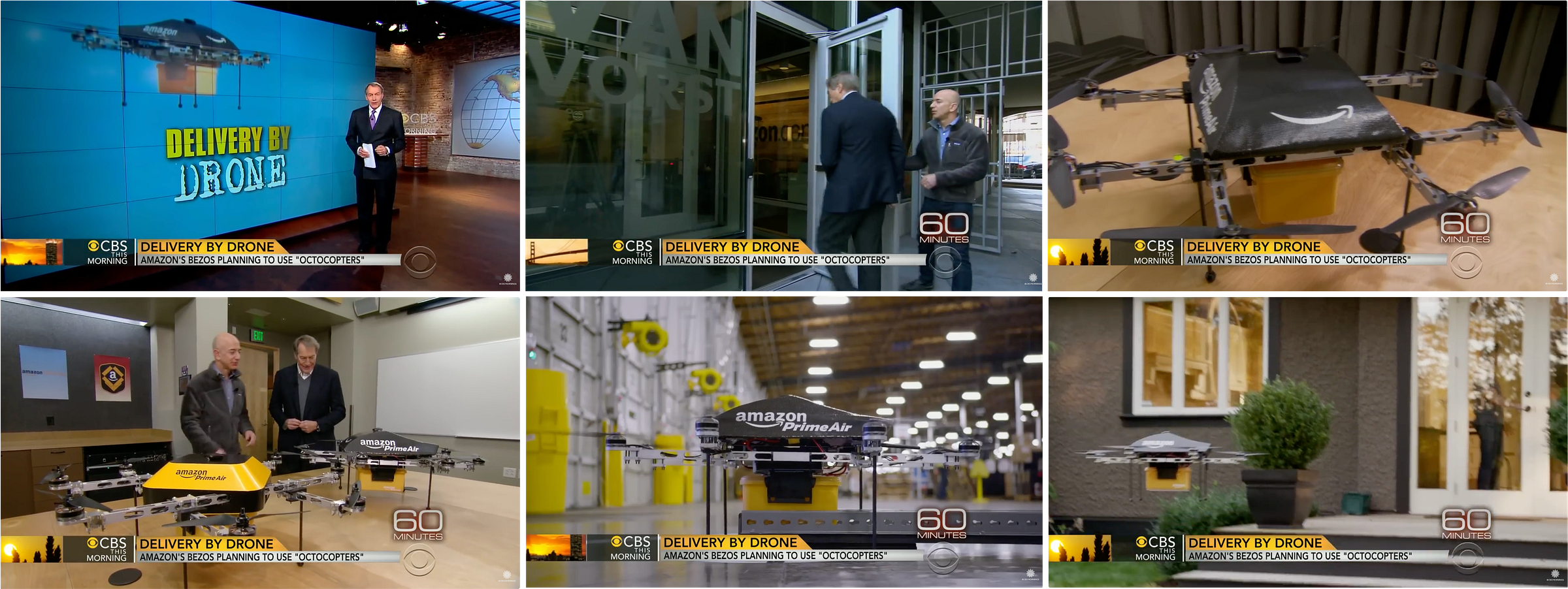

On 1st December 2013, Amazon founder and then-CEO Jeff Bezos had a surprise in store for correspondent Charlie Rose during the recording of their 60 Minutes interview. After the formal sit-down, Bezos walked Rose into a mystery room at the Amazon campus in Seattle and revealed a secret R&D project: ‘Octocopter’ drones that would fly packages directly to your doorstep in 30 minutes. “I know this looks like science fiction - it’s not,” Bezos proclaimed.

The drones he revealed were of a similar species to the camera drones we touched on in the paragraphs above. Amazon’s bespoke versions were designed to carry five pounds of weight (covering 80% of the packages they deliver), and capable of flying upto a 10 mile radius from Amazon’s fulfilment centres. They were electric-powered (and thus emission free), and would autonomously deliver packages to customers based on GPS-guided coordinates.

Assuming the company could surmount the formidable obstacles of safety, reliability and regulation, Bezos estimated that ‘Prime Air’ would be fully live within the following 4-5 years. With that, he had unwittingly fired the starting gun for the era of drone delivery - set to be the killer use case for consumer drone technology in the decades to come.

But 12 years later, if you peek outside your window today, chances are you won’t see fleets of flying robots in the sky, dutifully delivering people’s packages. Despite spending billions of dollars on the programme, Bezos’ vision never quite panned out. Due to a combination of technical challenges, financial constraints, glaring safety issues (and multiple crashes), regulatory backlash and public outcry, Prime Air has been a stop-start (but mostly stop-ish) effort at best. Despite an upgraded drone model released just last year, it’s still operating only on a trial basis in a handful of locations in Texas and Arizona in the United States.

To be fair to Amazon, they’re not alone in their struggles. The past decade has seen a parade of drone delivery hopefuls crash into the same wall: regulators choosing to play safe, technology that wasn’t quite ready for prime time, and math that simply refused to work.

So, returning to our original timeline. If, like Naman, you were looking for a model of a successful drone delivery operation in 2020, to use as inspiration for a ‘contactless delivery’ use case, Amazon would represent a dead end. And if Amazon - i.e. the Beyoncé of last mile innovation - couldn’t figure out how to transport stuff using drones, you might reasonably assume that no one else could either.

Enter Zipline.

4. Bundle In The Jungle

It would be disingenuous for us to embark on a piece about drone delivery without first spending some time talking about Zipline.

Zipline is to drone delivery what Iron Man is to the Marvel Cinematic Universe. It’s the thing that proved this thing could work - at scale. It was the first entity to crack the code, as the (American) company that legitimised the domain of autonomous aerial logistics.

So why haven’t you heard of it? Why isn’t it as ubiquitous a name outside (and even inside) of America as other emerging tech heavyweights, the same way Waymo is for self-driving cars or Neuralink is for brain-computer interfaces? Well, the simple answer is that despite being born in the Western world, the company’s most profound impact has been thus far felt in Africa.

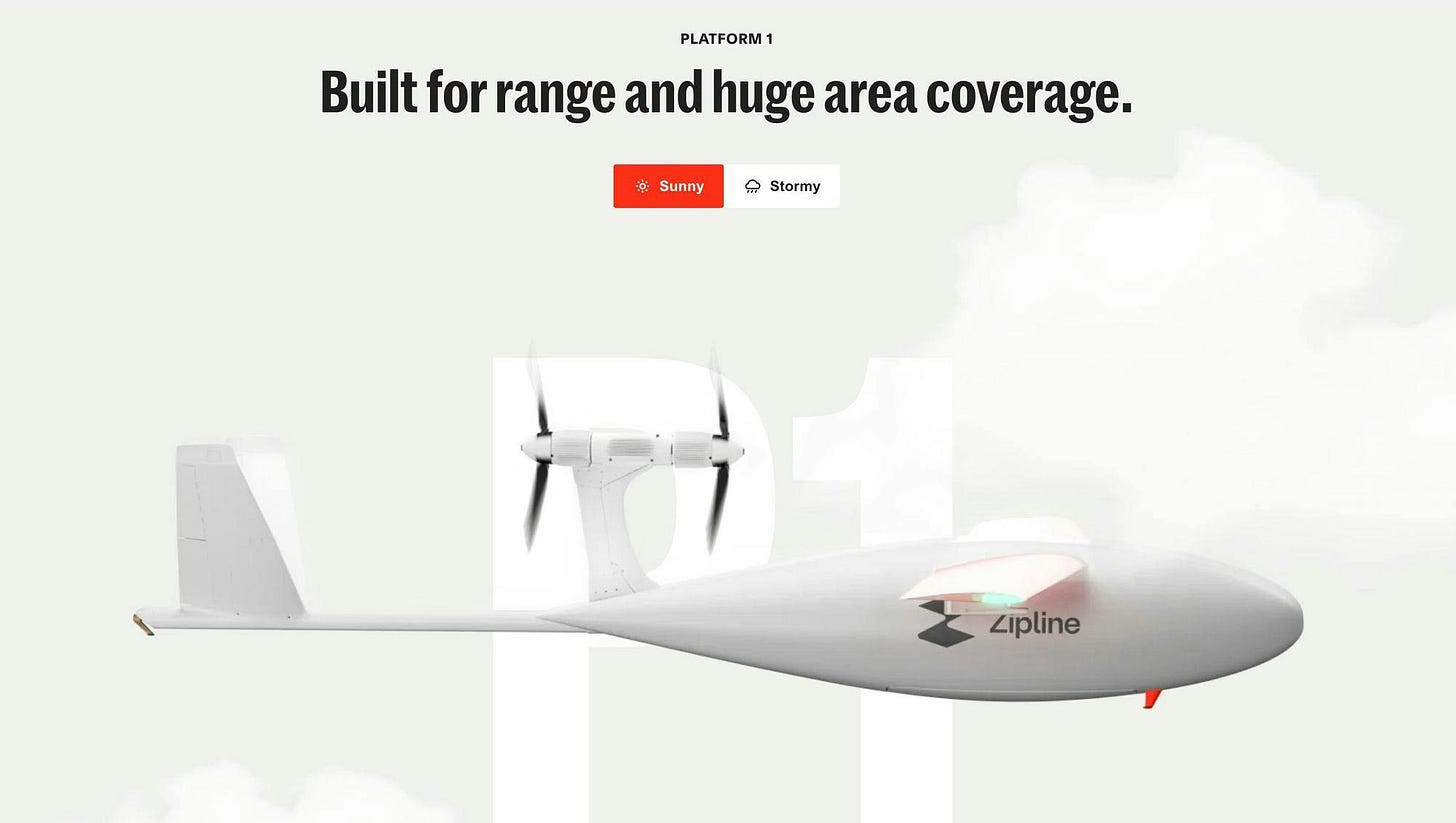

Zipline emerged from a cauldron of Silicon Valley ambition and global health necessity. It was founded in 2014 by Keller Rinaudo-Cliffton, Keenan Wyrobek, and William Hetzler - a trio whose backgrounds spanned robotics, automation, and aviation. The company’s foray into drone delivery was sparked by a sobering discovery during field research in Tanzania, where they encountered tale after tale of unfortunate deaths that could have been prevented by timely access to blood, antivenom, and other medical supplies.

Spurned by regulatory sluggishness in the US, Zipline’s breakthrough came in 2016 when the Rwandan government signed a deal with the company to facilitate emergency blood deliveries to regional hospitals outisde the nation’s capital. The aerial route allowed them to bypass Rwanda’s sordid road infrastructure, which was largely unpaved and often treacherous. Today, more than 75% of blood deliveries in Rwanda outside of Kigali are done by Zipline drones, and academic studies have shown a >50% reduction in infant and maternal mortality where its service operates, and a >60% reduction in both blood wastage and vaccine stockouts.

The company today has expanded its medical drone delivery service to other countries in Africa including Ghana, Nigeria, Kenya and Côte d’Ivoire. Since commencing operations in the continent, they’ve now flown over 120 million autonomous miles across 1.5 million+ individual flights around the world. Today their network serves 5,000 hospitals and health facilities across eight countries, delivering everything from blood to antivenom to vaccines and cancer medications, embodying its self-professed status as “the largest commercial autonomous system on Earth”.

After proving its technology in geographies and use cases with the most pressing requirements for faster alternative transport (with zero human-related safety incidents recorded in over ten years), Zipline has made headlines in 2025 with its moves closer to home.

After years of regulatory hurdles, a newly progressive US Federal Aviation Administration (FAA) has been forthcoming in its blessing of Zipline (and other companies) to begin drone deliveries in suburban areas of the United States. That’s meant partnerships with the likes of Walmart, Panera Bread, Sweetgreen, Cleveland Clinic, Chipotle and others to deliver everything from retail items to medical essentials to hot coffee to fresh burritos directly to people’s homes.

As it burrows deeper into the world of on-demand convenience in America after first solving for critical services in Africa, perhaps Zipline’s greatest achievement is in simply normalising the idea of drone delivery for its customers. What once seemed like science fiction has been quietly and painstakingly transformed into operational reality through millions of successful deliveries across multiple continents, proving that autonomous aircrafts can reliably move goods at scale.

In April 2023, the company raised a $330 million Series F at a $4.2 billion valuation, positioning it as the most valuable drone delivery company globally, and indicative of the size of the pie on offer for whoever can solve the fiendish puzzle of autonomous aerial logistics. “It’s very obvious that whoever succeeds will be one of the largest companies on Earth — bigger than United Parcel Service and FedEx combined,” says Zipline CEO Cliffton.

Unsurprisingly Zipline has been joined in this race by other global players like Wing (owned by Alphabet), Matternet, DroneUp, Manna, Flytrex and others (including Amazon) - each with its own unique model, configuration, specs and use cases - in a race to capture a slice of a market that is set to be worth $30.4 billion by 2029, with PwC projecting that the total value of goods delivered by drones could reach $65 billion by 2034…

…but we’ll put a pin in all that stuff for the moment. Now that you have some context, let’s return to where we left off.

5. So You Think You Can Drone?

My favourite sources of research for this piece were Naman’s blogposts from 2020 documenting his zero-to-one journey of starting Airbound in real time. They’re hilarious, partly because they were written for himself (vs any external audience), and partly because his tone alternates between prodigious engineer and regular self-deprecating 15-year-old kid reckoning with the task that lay ahead of him.

Exhibit A:

“…Whatever in the world made you think designing a novel drone would be a good idea when you have ABSOLUTELY NO EXPERIENCE in the domain. What do you mean you’ll just ‘figure it out’? This isn’t your cute little high school robotics competition.

…People have cobbled together flying doors before so just keep that as a benchmark and I’m sure you can make it marginally more aerodynamic than a porta-potty.

…Hey if it makes your ego feel any better, you can build the drone yourself. Call it a ‘novel innovation’, and you can continue telling yourself that you really did make a difference with what you built…Who knows, if you dedicate enough time to it, you could maybe even make something that’s not entirely useless…

…Fucking Amazon couldn’t do it and they think a child can

…As far as I’m aware, there isn’t exactly a YouTube tutorial on how to design your own drone from scratch.”

That last point turned out to be mostly untrue. If you’re curious enough and persistent enough, the Internet will eventually lead you to whatever it is you’re trying to find.

Internet resourcefulness was a more pronounced requirement in 2020, when there was no scope to access teachers (or teaching) offline.

“I basically immersed myself in this stuff,” Naman says. “I tried to learn everything I could about drones, about aviation, about aerodynamics, about composites etc. It turns out you can get a pretty good education on Youtube - like Real Engineering is an amazing resource. And whenever I reached a dead end, I would just hit up people that were actively working in these fields and ask them for advice. The physics of flight is pretty straightforward. At the end of the day it comes down to pretty basic physics, which isn’t hard to understand. What makes a difference though is how driven you are to ask the right questions.”

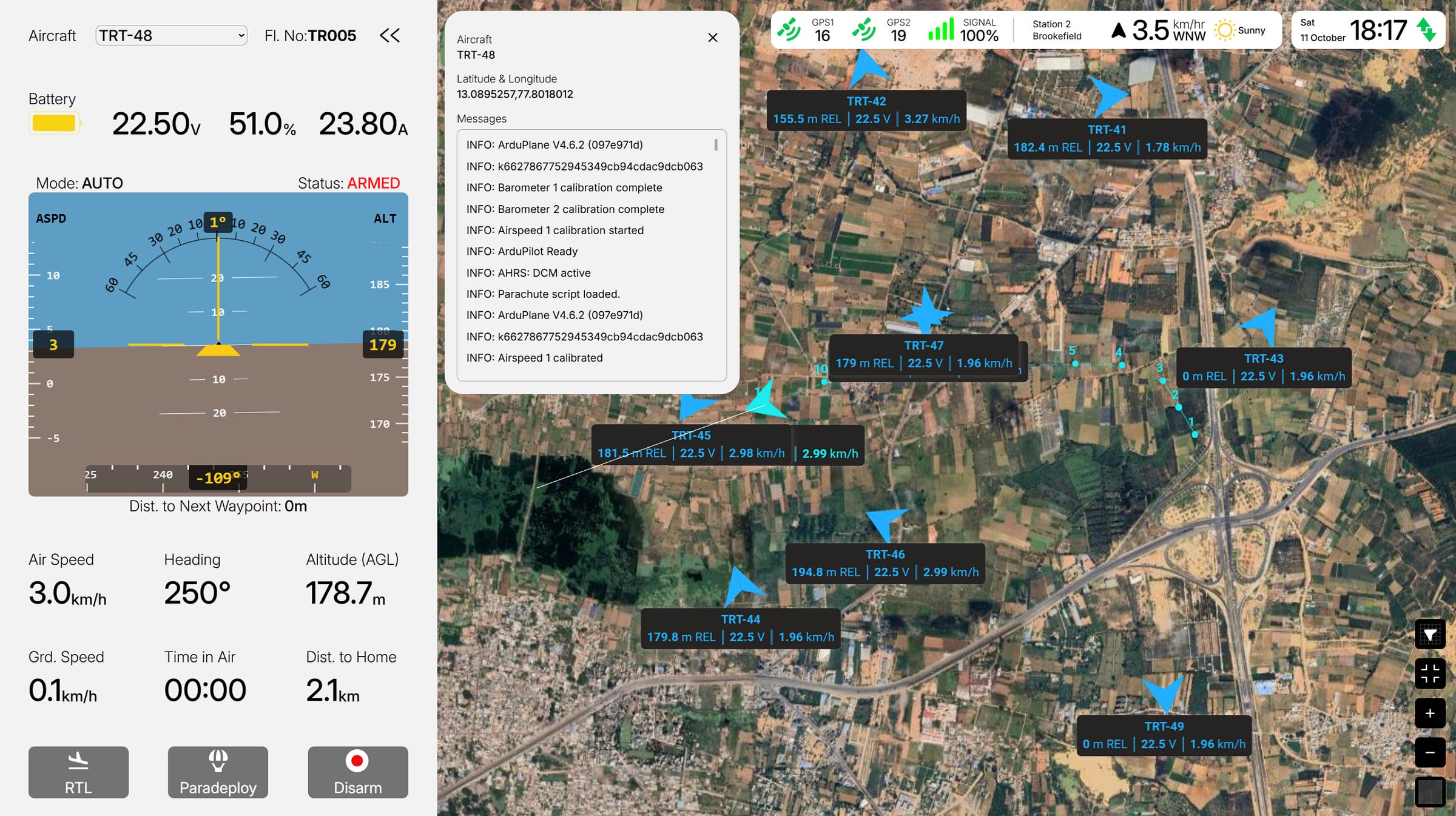

As he picked up the basics of making flight machines, Naman’s objective for the Helpful Engineering hackathon was to figure out the ideal configuration for a drone design that could fulfil the task of contactless delivery. For this he looked for inspiration across the global drone landscape, becoming acquainted with basic aerial photography drones as well as the heavier-duty machines being employed by Zipline in Africa. This introduced him to a broad taxonomy of drones, each saddled with a different set of trade-offs.

“Drones are actually a pretty diverse category,” he explains. “Clubbing all the different types of configurations under the umbrella of ‘drones’ is like describing both a bicycle and a Harley Davidson as a ‘two wheeler’. It doesn’t tell the full story. First you need to know where you’re trying to get to - then you pick the vehicle that’s best equipped to get you there.”

So when it comes to drones, what would you typically find in the garage?

6. Drones 101

At the most basic level, as we covered above, a drone is any flying vehicle that operates without a human pilot on board.

It includes everything from tiny palm-sized toys used for backyard photography to massive military aircrafts designed for long-range warfare. Broadly speaking, drones are classified by their different design and flight capabilities, of which - for the sake of simplicity - there are three main types:

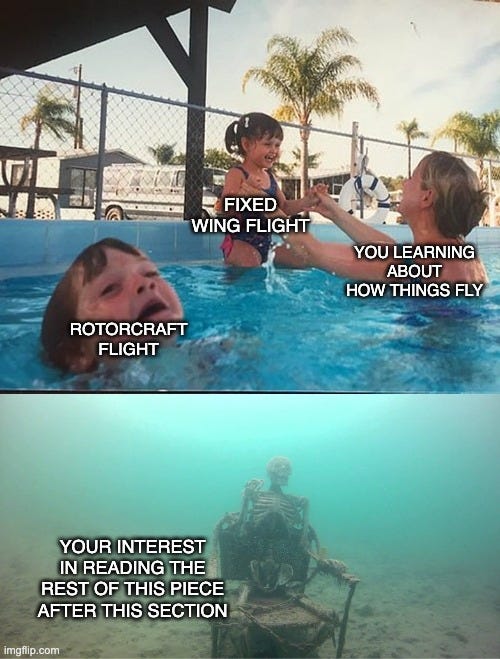

1. Multi-rotor drones are what most people picture when they hear ‘drone’. These are powered by multiple spinning rotors (i.e. propellers) on top. The most common arrangement features four rotors, hence the colloquial name of ‘quadcopter’. They can hover stably in one spot and move in any direction, making them great for taking pictures or inspecting things up close. The downside is they drain their batteries quickly (because their rotors have to constantly keep spinning to keep them hovering in the air) and thus can’t fly very far.

2. Fixed-wing drones look like small airplanes. They typically use an electric motor-powered propeller to push forward in the air. They require forward motion to lift off the ground, and need to keep moving forward to stay in the air, just like regular planes - their wings are shaped to keep them in the air during forward flight. They’re much more energy efficient than quadcopters and can fly long distances, but they need space to take off and land (like a runway or a catapult launch system), which makes them less flexible for everyday use.

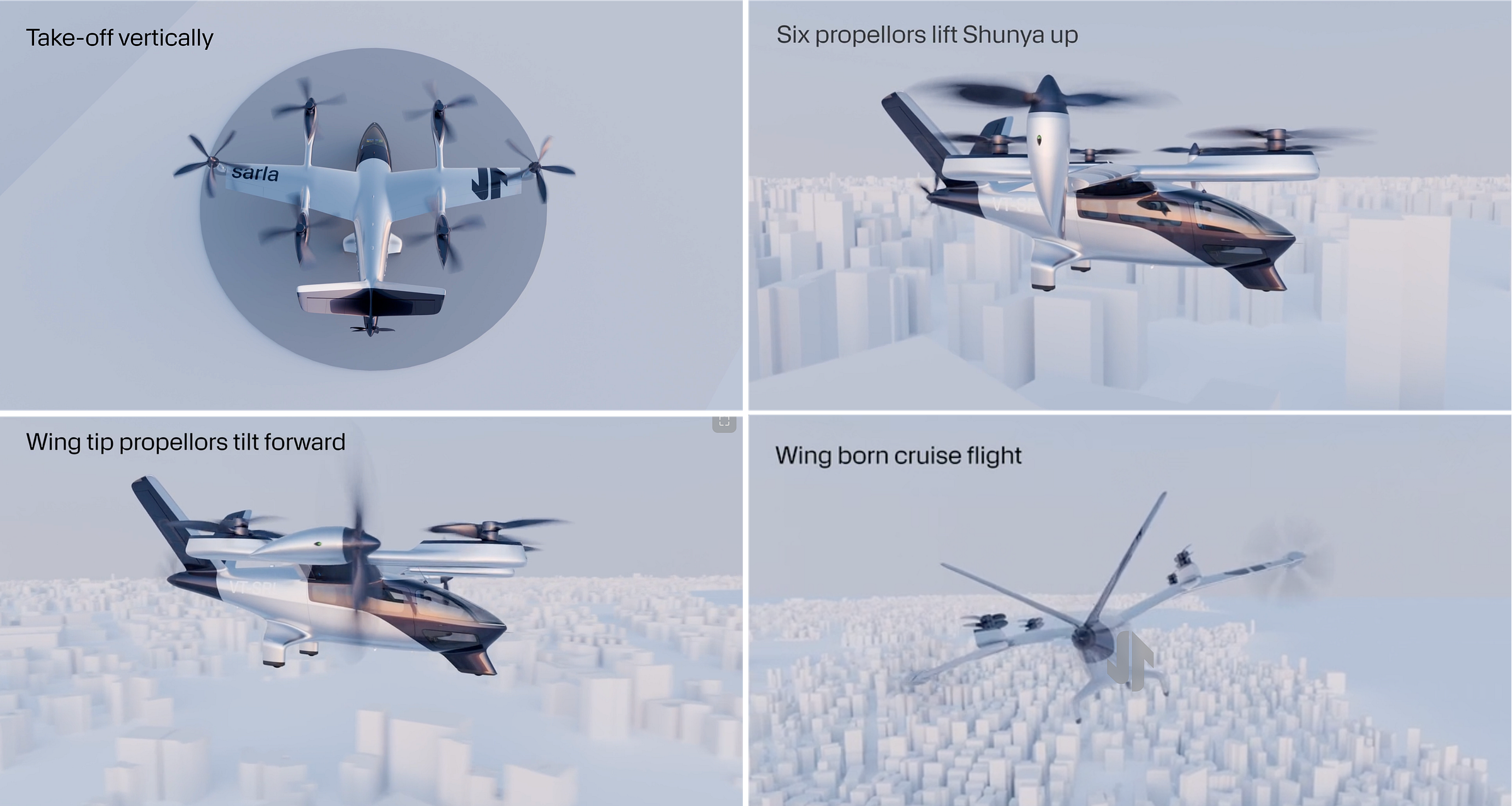

3. Hybrid VTOL (Vertical Take-off and Landing) drones aim to get the best of both - they can take off straight up like a helicopter but then fly efficiently like a plane. Some designs literally just mash the two together - taking a fixed-wing drone and sticking rotors on top (called a quadplane), while others use more creative approaches (like tilting the rotors or rotating the entire aircraft) to solving the problem of taking off vertically and then flying forward like a plane. VTOL remains one of the most challenging problems in aviation engineering because no single design has emerged as the clear winner.

Each of these designs represents different engineering solutions to the same fundamental challenge: how to lift an object into the air and keep it there as efficiently as possible, or how to generate enough upward force to overcome gravity while minimising energy consumption.

To appreciate the design of Airbound’s eventual solution (and understand various terminology that will soon be slathered all over this piece) - it probably helps to know the basic physics of flight. If you’re an engineer or an aviation nerd, you can probably skip ahead to section 8. But for those of you who slept through Physics class, here’s a brief explainer on how things fly courtesy of our friends at…

7. The ‘How Things Fly’ Explanation Station

So…how do things fly?

We’ll start slow.

To keep things simple, we’ll explain this stuff using an aircraft for reference. (btw the plural of aircraft is also ‘aircraft’, not ‘aircrafts’, which is totally messed up, I know, but I didn’t make the rules).

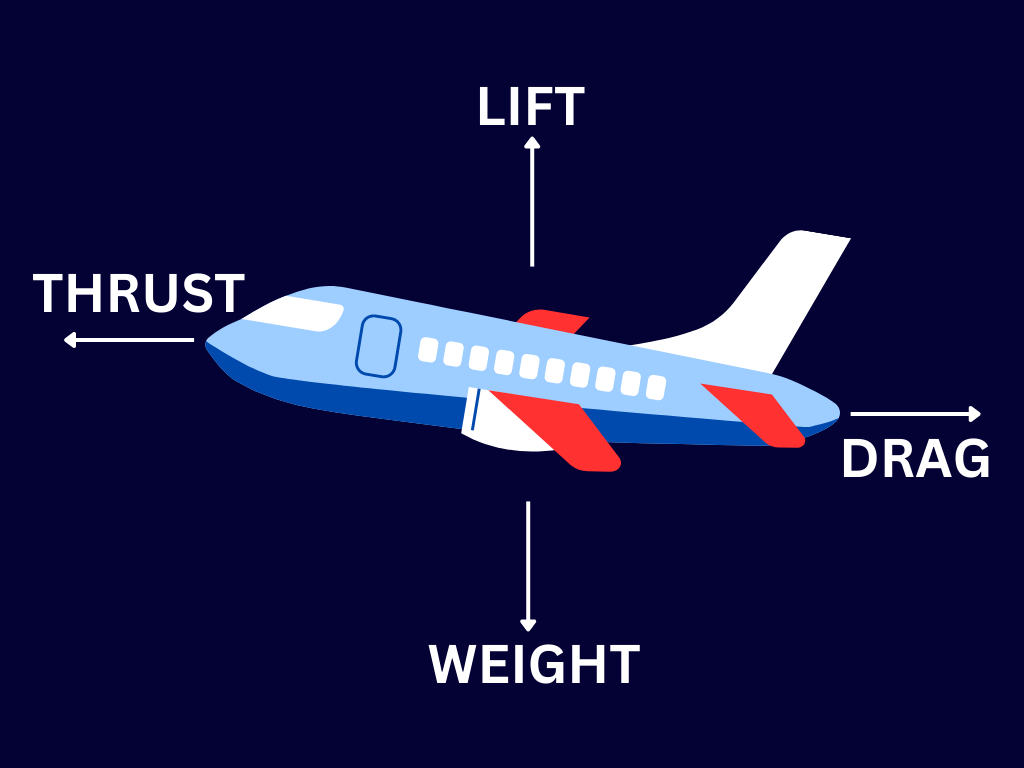

Anyway, aircraft (and all things in general) fly by balancing four forces: lift, weight, thrust, and drag.

Lift is the upward force that keeps aircraft airborne.

Weight is gravity pulling the aircraft down. For flight to work, lift must equal or exceed weight.

Thrust pushes the aircraft forward. Engines or propellers create thrust by accelerating air backward, which shoves the aircraft forward.

Drag is air resistance fighting against forward motion. Everything from the aircraft’s shape, to how its parts are attached, to the texture of its surfaces, creates drag that engines must overcome.

The key insight is that these forces balance each other out. When a plane speeds up, it gets more lift (more air flowing over the wings) but also more drag (more air pushing back against it). Pilots control this by using the throttle to go faster or slower, and by tilting parts of the wings to change how much lift they generate (via those little flaps you see from the window seat of your airplane).

The engineering challenge is designing aircraft that maximise lift and thrust while minimising weight and drag—a delicate calculus— which is why aviation engineers obsess over every gram and surface detail.

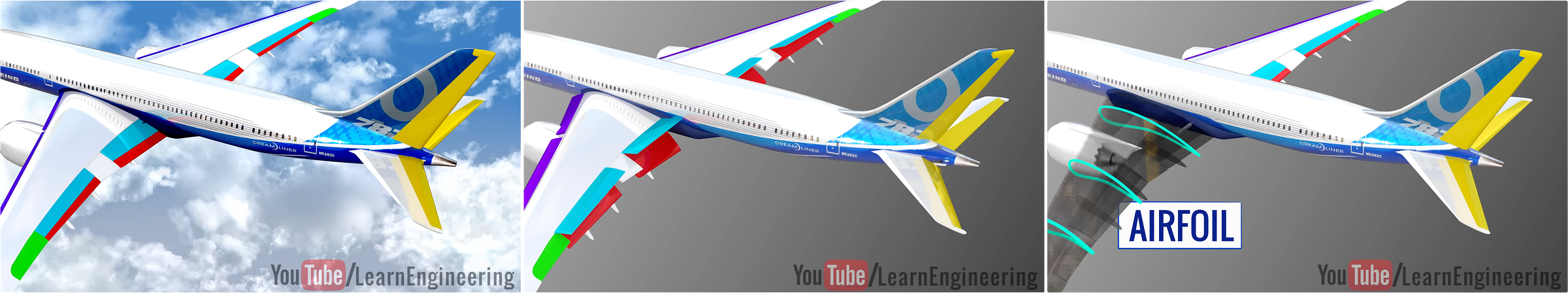

Let’s get practical. How does this work for a commercial airplane (and therefore, also for a fixed-wing drone)?

For a commercial airplane (and fixed-wing drones), here’s how the physics works in practice. Don’t worry about the technical jargon, it’ll all make sense soon.

So, on one team, you have Thrust and Lift.

Thrust comes from jet engines or propellers that accelerate air backward at high speed. This creates an equal and opposite reaction that pushes the aircraft forward—the faster you push air back, the more thrust you generate. (This is also why Zipline uses an electric catapult to launch its P1 drones—it gives the aircraft enough initial velocity for the wings to generate lift)

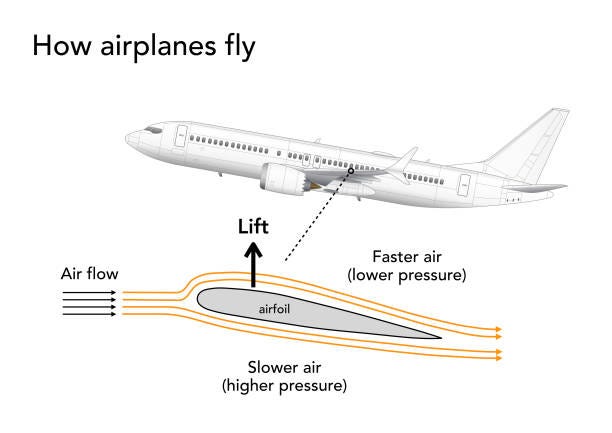

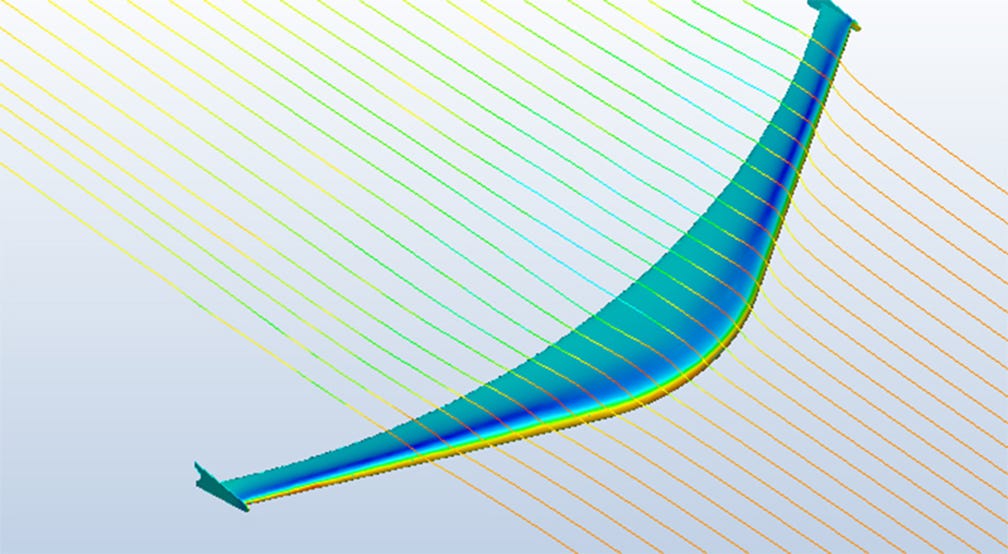

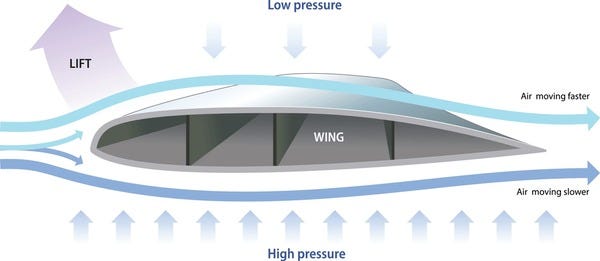

Lift is where it gets interesting. Aircraft wings have a curved shape.

Another view with some science-y labels.

This curved shape forces air to travel at different speeds over the top and bottom surfaces. According to Bernoulli’s principle (which I didn’t know about till just now), faster-moving air creates lower pressure, so the higher-speed airflow over the curved top creates a pressure difference that literally sucks the wing upward.

But wait, there’s more.

Wings also deflect incoming air downward. Per Newton’s third law, pushing air down creates an upward reaction force that also produces lift. So it’s a one-two punch that forces the airplane into the air. However, it’s the pressure difference (highlighted in the paragraph above) that does most of the heavy lifting. (Don’t worry about remembering any of that - all you need to know is that curved wings create an upward force when air flows over them fast enough).

Weight and Drag are the opposition forces. Weight is straightforward—gravity pulling everything down. Drag comes from air resistance against the aircraft’s shape, surface friction, and turbulence created as the plane pushes through air.

The elegant part is that once an airplane is moving fast enough, the wings generate lift automatically—it doesn’t need to constantly burn fuel to stay airborne like a helicopter does. The engine’s primary role at that point is to produce just enough thrust to overcome drag and maintain forward speed. This is why fixed-wing aircraft (including drones like Zipline’s P1) are so much more efficient for long-distance flight. The engine only needs to maintain forward speed; the air flowing over the wings takes care of the rest.

The headline metric here is the ‘Lift-to-Drag’ ratio (L/D ratio)—basically how much upward force you get for every unit of resistance you face. A good commercial airplane might have a ratio of 20:1, meaning it gets 20 units of lift for every 1 unit of drag. So if it’s gliding at a constant airspeed with no power, it’ll move forward 20 metres for every one metre it descends. This also means it only needs 1/20th of its weight in thrust to maintain level flight—i.e. a 100kg aircraft needs just 5kg of thrust to stay airborne.

And for a quadcopter? The L/D ratio is around 1:1, meaning a 100kg quadcopter needs 100kg+ of thrust just to hover. That’s why fixed-wings dominate long-distance flight.

Say more about the curved wings. Also why do the shape of the wings matter at all?

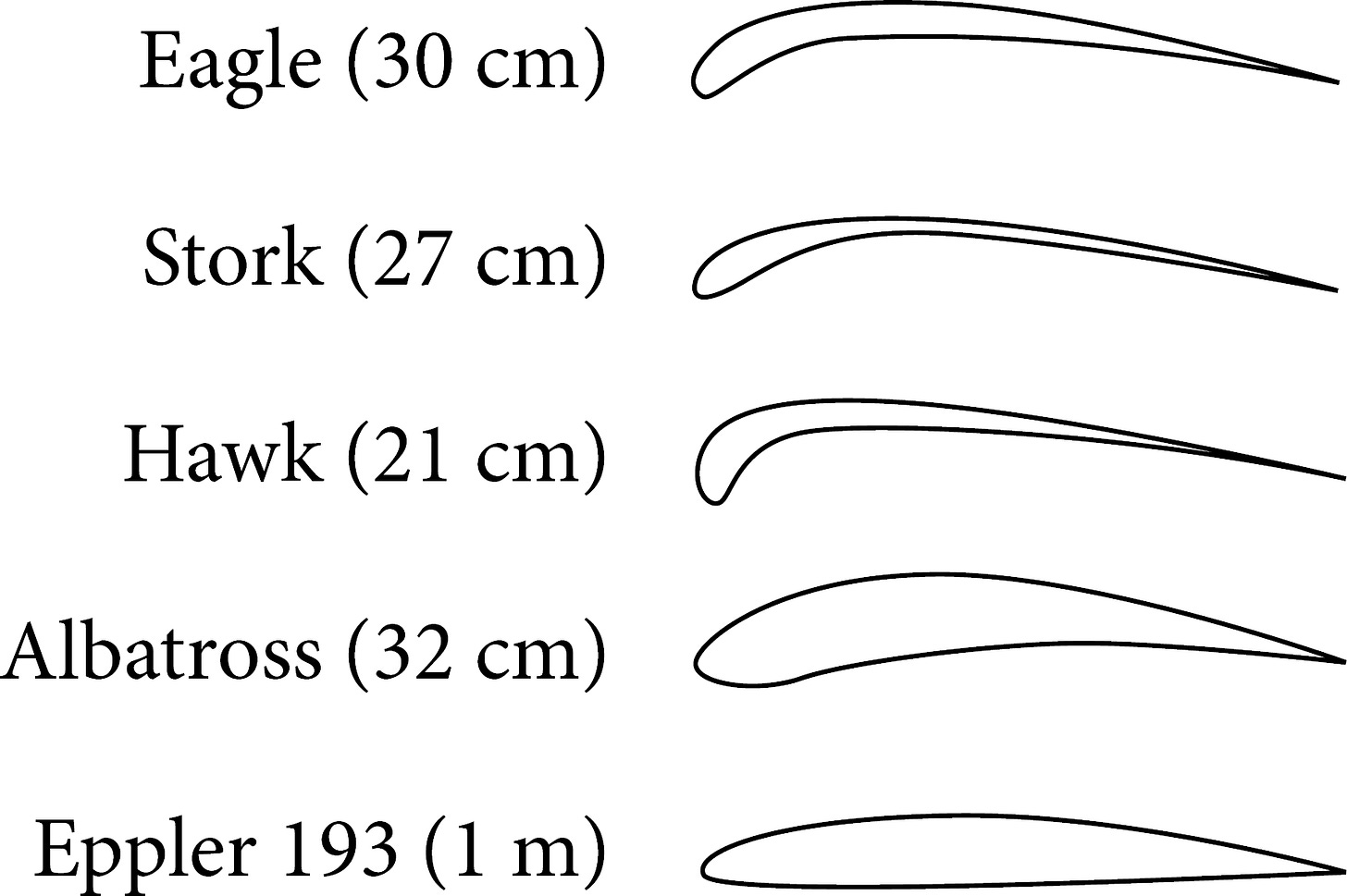

To recap, yes, aircraft wings have a curved shape - and that curve counts for everything. The technical term for this kind of specially curved shape is an ‘airfoil’. It’s what you’d see if you cut a wing in half and looked at its side profile - curved on top, flatter underneath. This shape is designed to produce lift when air flows over it. This isn’t some arbitrary design choice; it’s science, bro.

Wing shape determines how efficiently an aircraft flies. A flat wing does a poorer job of generating lift because there’s no differential airspeeds or pressures - all it does is deflect air downwards thereby generating a little bit of upward reaction force. A flat wing could technically generate lift, but it would be like trying to slice through water with your hand held flat and rigid - it pushes water aside but creates a huge wake of churning water behind it. Curve your hand slightly, and you can slice through much more smoothly with less resistance.

Nature figured this out first. Bird wings aren’t flat boards but carefully curved surfaces that slice through air cleanly i.e. they’re airfoils.

It’s no coincidence that the Wright brothers made some of their biggest breakthroughs by obsessively studying the flight of birds, despite intense ridicule from their friends who called them Birdheads (I made that last part up).

Genuinely though, the Wright brothers respected birds as nature’s master aerodynamicists. They observed how birds twisted their wingtips to maintain balance in gusty winds—one tip angled up, the other down—which directly inspired their revolutionary control system that allowed pilots to steer by flexing the aircraft’s wings. They also noticed that bird wings weren’t just curved, but had different curves along their length—thicker near the body, tapering toward the tips (just like a modern airplane), creating an efficient airfoil shape that generated maximum lift with minimal drag.

And crucially, they observed that birds could glide for extended periods without flapping by using rising air currents and maintaining the perfect angle relative to the wind—proving that sustained flight wasn’t about raw power but about working intelligently with aerodynamic forces. This biological research directly informed their aircraft design, proving that nature had already solved the aerodynamics puzzle millions of years before humans attempted powered flight.

Respect to Nature.

Word.

If you want to get really cute here, the shape of an airfoil - which kind of looks like an elongated teardrop - is nature’s default aerodynamic shape. Think of how raindrops form as they fall, or the streamlined bodies of fish and dolphins. This shape minimises turbulence by allowing air to flow smoothly around it, dramatically reducing drag—nature’s solution for efficient movement through fluids.

So show some appreciation for the teardrop - it’s the shape that evolution and engineering keep rediscovering because physics don’t lie.

Anyway, back to business.

Modern aircraft wings are essentially stretched teardrops: curved enough to generate lift, but streamlined enough to slice through air efficiently.

In fact, modern engineering has adopted this teardrop principle everywhere that matters. Propeller blades use airfoil shapes to grab air efficiently and convert engine power into thrust. Even seemingly minor components like wing struts and antenna housings are shaped to minimise drag. For aviation (and drone) engineers, this becomes critical: every surface that meets airflow either helps or hurts lift. Every little detail can be a boost or bust for aerodynamic efficiency.

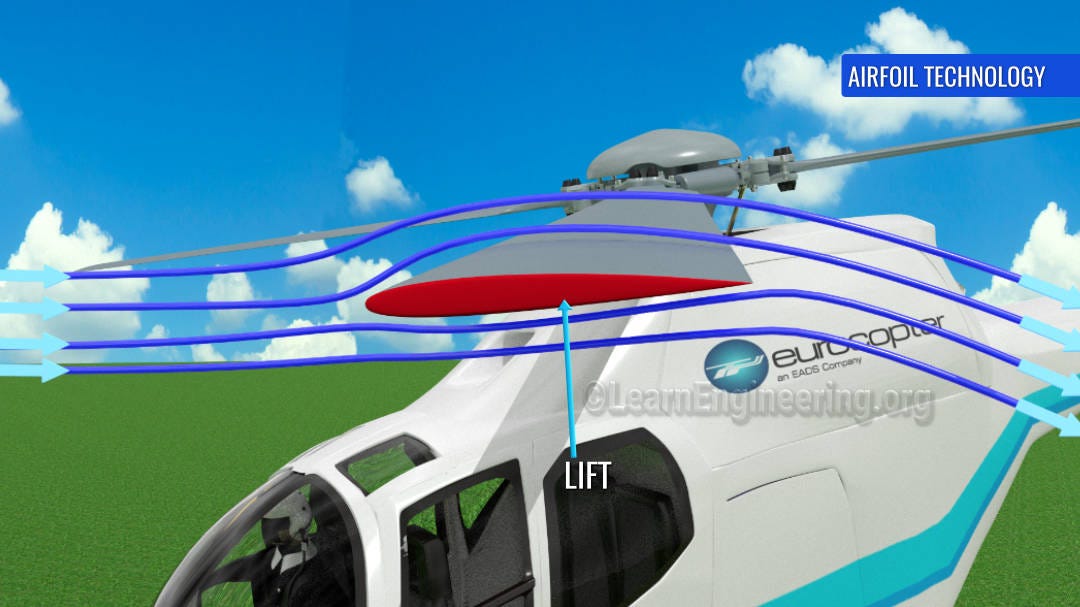

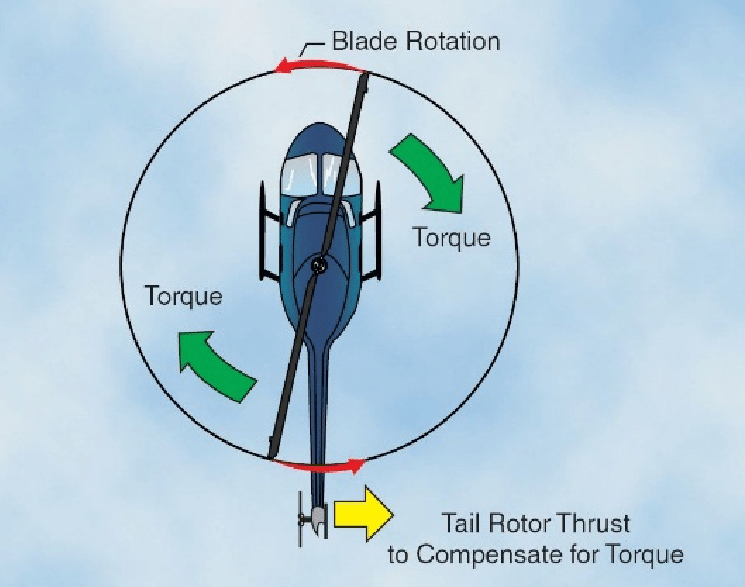

So this is all for fixed-wing flight right? How does this work for something like a helicopter? (I assume a quadcopter drone would have a similar vibe?)

Yes. By the way, helicopters and quadcopters are generally classified as ‘rotorcraft’ because they use rotating blades for lift. The terminology is messy though, because many VTOLs also classify as rotorcraft despite having fixed wings (because they have propellors aiding vertical take off and landing).

For our purposes, let’s focus on the key distinction: pure rotorcraft like quadcopters and helicopters rely entirely on spinning rotors for lift.

“Why not ‘propellercraft’?”, I hear you say.

The main difference lies in their function and design: a propeller primarily creates thrust to move an object forward (like in a commercial airplane), while a rotor generates both lift and thrust simultaneously by spinning horizontally (like in a helicopter)—though both are essentially spinning airfoils generating force by accelerating air.

In fact, if you look at a helicopter, each rotor blade is actually a small rotating wing if you examine it closely.

As the blades spin, they slice through air at an angle, deflecting air downward. Newton’s third law kicks in: push air down, and you get pushed up. The faster the rotors spin, the more air gets deflected downward, and the more upward force (lift) is generated.

This gives rotorcraft incredible advantages—they can hover, move in any direction, or even fly backwards. But it comes with a major cost: energy efficiency. Every moment of flight requires the rotors to spin fast enough to support the aircraft’s full weight against gravity. It’s like how a hummingbird has to furiously hover to stay in the air vs how an albatross can gracefully glide across the sky. There’s no ‘free lunch’ from forward motion (like fixed-wing aircraft enjoy).

Think of it this way: rotorcraft-flight is like flailing to stay afloat in one spot if you were swimming in the sea — you must constantly expend energy to stay in one place. Airplane flight is like floating on your back—once you’re moving, staying afloat becomes much easier. This is why delivery drones designed for long distances, like Zipline’s P1, use fixed-wing designs rather than quadcopter configurations. The physics simply favour efficiency over manoeuvrability for extended flight.

Ultimately all of this is an energy game?

Yes. In aviation, the crown goes to the most energy efficient system.

Remember how we teed up this section? We were talking about how different drone configurations are basically different routes on how to ‘generate enough upward force to overcome gravity while minimising energy consumption’.

Flying anything requires constant energy to stay airborne. Unlike a car that can coast downhill or a boat that can drift with the current, aircraft must continuously burn fuel to generate the forces needed for flight—thrust to move forward, and lift to stay up. This makes commercial aviation fundamentally an energy efficiency game. The more efficiently you can generate lift and thrust, the less fuel you burn, the further you can fly, and the cheaper your operations become.

This energy reality shapes everything about aircraft design, turning it into a relentless optimisation exercise. Airlines spend billions developing lighter materials (like carbon fibre) for their structures because every kilogram of weight requires more fuel to lift. It’s the reason why they use lighter catering trolleys and ultra-thin paint, and even remove thick magazines from the backs of seats. It’s why aviation engineers obsess over wing shapes that reduce drag even by 1% because smoother airflow means engines work less hard (meaning millions in cumulative annual cost savings on fuel).

For cargo companies, this translates directly to cost per kilogram—how much does it cost to move one kilogram of stuff from point A to point B? The most efficient aircraft wins because it can offer the cheapest cargo rates (because fuel represents 25-30% of total airline operating costs, meaning every ounce of efficiency gain will directly impact profitability).

This is why airline companies are interested in parameters like the aircraft’s strength-to-weight ratio (more strength for less weight is ideal); and payload-to-weight ratio (which is the relationship between useful cargo - called ‘payload’- and the aircraft’s own structural weight) because the higher this ratio, the more revenue-generating cargo you can carry relative to the dead weight of the aircraft itself. (FYI a payload can refer to passengers, packages, freight etc).

This is also why the history of aviation reads like a century-long war against weight and drag - every breakthrough, from the Wright brothers’ wing warping to modern composite fuselages - has been about doing more with less (energy).

And voila, now you know how things fly. Here’s a cookie for making it through all that.

…Oh, sorry, one last thing. Although the determinants of energy costs are slightly different for delivery drones - which use electric batteries rather than fuel - the objective is the same: find a way to carry the maximum payload as efficiently as possible, which is a function of both the raw weight of the aircraft and the ingenuity of its design…

8. Drones 102

“I didn’t know anything about aerodynamics. I didn’t have an engineering degree. I wasn’t brought up in an environment where I knew the industry standard. I had never heard of a payload-to-weight ratio or a lift-to-drag ratio or any of that. I was just trying to figure out how to make the best delivery drone, and as a kid in the 11th grade, I needed to figure out how to make this as cheaply as possible.”

The term ‘first principles’ tends to be bandied about quite flippantly in startup circles these days. But Naman had no alternative but to begin with a clean slate, which imposed both the burden of building from zero and the luxury of being unencumbered by conventional wisdom - a twin furnace within which his drone design was ultimately forged.

This exploration began by studying the tradeoffs between the two dominant drone configurations.

Naman explains that “quadcopters are focused more on software and what kind of services you can integrate with them - aerial photography, crop spraying, firefighting etc. There’s very little you can do to differentiate on the hardware. Sure, you can have a slightly lighter frame or slightly better propellers, but aerodynamics don’t really matter with a quadcopter — it’s more about integrating electronics and software. You’re not so concerned about your lift-to-drag ratio when you need to spray a small parcel of land with fertiliser. But when you’re looking at fixed-wing drones — think about the engineering that goes into a Boeing 737 — you’re now dealing with questions like how do I make the structure more lightweight, how do I make it more fuel efficient, how do I improve the aerodynamic efficiency. Because if you’re in the business of moving things from point A to point B, this is what matters.”

Naman’s research naturally led him to Zipline, which was then (and still is now) the most established global drone delivery company by scale and operational experience.

“What they had achieved was amazing,” he says. “But it just needed so much infrastructure. It needed so much space for takeoff and landing. In my head I was like ‘it’s a drone, why can’t it just take off and land vertically?’”

Initially just looking for something that could get off the ground without much trouble, the first design that Naman conjured up for the hackathon was something akin to “an aerodynamic quadcopter”. It had six rotors instead of four - i.e. a hexacopter. “It was really ugly. My friends said it looked like a fat turtle. It was also just too bulky for long distance delivery.”

The aerodynamic shortfalls of rotorcraft convinced him to abandon that course. Realising that neither quadcopters or fixed wing drones could truly meet his requirements, he began looking for middle ground. “Someone I had reached out to pointed me in the direction of Hybrid VTOLs,” Naman recalls.

To recap, Hybrid VTOLs (also just called VTOLs - Vertical Takeoff and Landing drones) - are drones that can take off vertically like a quadcopter and then fly forward like a fixed-wing drone. (The name is confusing because a quadcopter technically also takes off and lands vertically, but I guess aviation people aren’t that good with naming stuff). Anyway, with VTOL the idea is to combine the low infrastructure requirements and precise positioning of a rotorcraft with the energy efficiency of a fixed wing aircraft. The most common incarnation of a delivery drone VTOL is a ‘quadplane’ - which basically looks like a fixed-wing drone with a bunch of rotors stuck on top.

How does a VTOL achieve the necessary speed for fixed wing flight without a runway or a slingshot-y thing? During takeoff and landing, the four rotors spin to provide vertical lift. Once airborne, the quadplane transitions to forward flight by firing up a separate propeller (usually mounted at the front or back) while gradually reducing power to the vertical rotors. As speed increases, the fixed wings begin generating lift through normal aerodynamic principles (which you and I are now experts in yeah?), and the vertical rotors can be shut down entirely, turning the aircraft into a conventional plane for efficient long-distance flight. The transition back to vertical flight reverses this process—slowing down until the wings can no longer support the aircraft, then spinning up the rotors again for a controlled vertical landing.

“Quadplanes are just so inelegant,” says Naman, with genuine pain in his voice. “Sure, they’re stable and yes, they’re relatively easy to build, but it stinks of engineering laziness. When you stick propellers right in the middle of fast-flowing air over the wings, you’re directly interfering with lift generation and creating massive drag. This is the design you make when you don’t care about aerodynamic efficiency.”

Even outside of interfering with lift, quadplanes have an inherent wastefulness embedded in the design. During vertical flight, the fixed wings and forward propeller become dead weight that must be lifted without contributing to thrust. During forward flight, the four vertical rotors become parasitic drag—essentially expensive paperweights bolted to the aircraft that create air resistance while serving no function. And worse, as Naman lamented, the rotors sit directly in the airstream flowing over the wings, disrupting the smooth airflow needed for efficient lift generation.

“There are other VTOL configurations that are interesting too, some better than others,” says Naman, “but nothing really met my requirements for aerodynamic efficiency…until I found the tailsitter.”

9. Tailsitter

“If you’re curious enough and persistent enough, the Internet will eventually lead you to whatever it is you’re trying to find.”

- Me quoting myself from earlier in this piece (what? you gonna call the police?)

Much like it does for many teenage boys, the Internet would cough up two pieces of media that would bring Naman much excitement.

“First I found this Youtube video from the Aeromodelling Club at IIT Kanpur showing this drone concept called a tailsitter. I was like ‘Ok this is what I’ve been looking for, this is what I need to build’.”

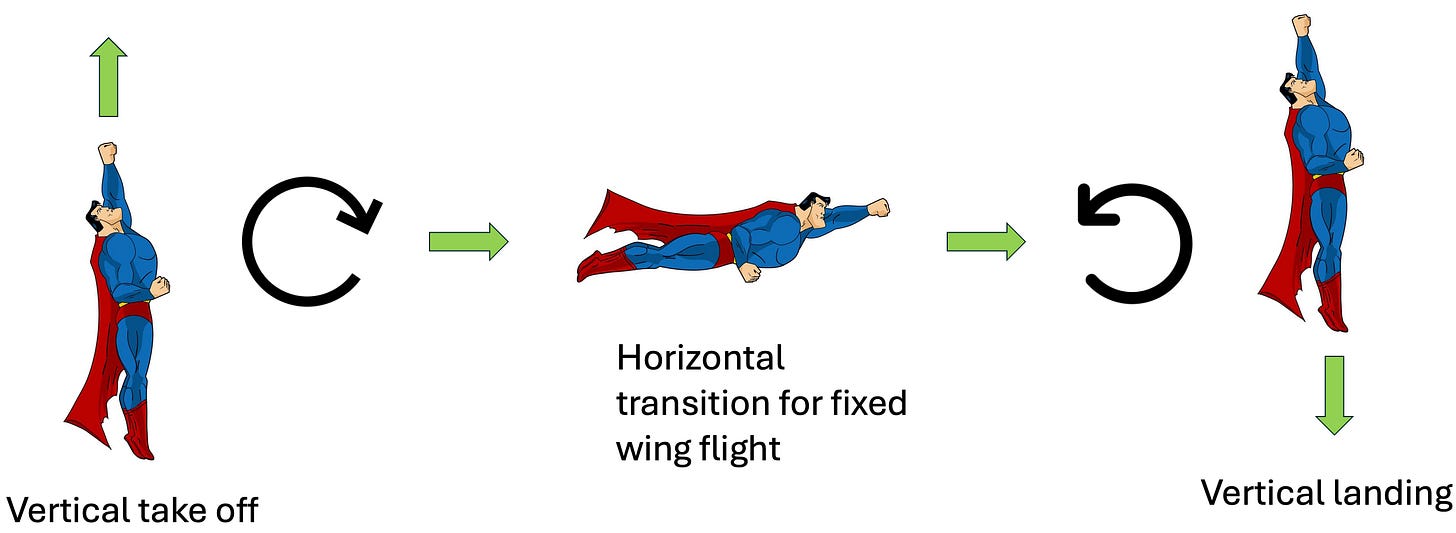

The tailsitter is one of aviation’s most conceptually elegant yet practically challenging designs, first developed during World War II as engineers sought aircraft that could take off from small spaces without runways. The aircraft takes off vertically like a rocket—sitting on its tail with the nose pointing straight up—then rotates 90 degrees in mid-air to fly horizontally like a conventional airplane.

The appeal lies in its mechanical simplicity: tailsitters use the same propellers and ‘control surfaces’ (the moveable parts like rudders and flaps that control direction and stability) for both vertical and horizontal flight, eliminating redundant systems and reducing weight.

However, the transition phase - when the aircraft pivots from vertical to horizontal flight - is especially tricky. It requires sophisticated flight control software to manage the spatial reorientation—essentially programming the aircraft to smoothly flip from rocket-like vertical flight to airplane-like horizontal flight while maintaining stability.

Despite decades of development, tailsitters remained largely experimental curiosities until modern flight computers and autonomous systems made the complex control algorithms manageable, leading to renewed interest from companies building small autonomous aircraft where the design’s efficiency advantages outweigh its control complexity.

“One of the advantages of being a young engineer is that you get to be naive and idealistic,” Naman admits. “The difficulty of building a tailsitter wasn’t top of mind for me. I was just drawn to the fact that you could use the same controls, the same propeller, the same motor for vertical and horizontal flight. You’re reducing parts. You’re reducing points of failure. The same mechanism is used for multiple things. To me that is engineering elegance. I was a fan.”

The tailsitter became the template for his dream drone design.

He created a digital rendering of a tailsitter drone that could theoretically (and perhaps quixotically) perform the task of home delivery. He dubbed this initiative the ‘OpenDrone’ project. It was the end point of his efforts during the week-long Helpful Engineering hackathon in August 2020, which he ended up winning. It entitled him to $500 of prize money.

That princely sum would represent his initial seed funding. “It was six months before I could actually access these funds though, because of banking issues with transferring the money,” Naman says. “Finally by the end they just ended up paying for a bunch of supplies and materials directly. The delay was pretty annoying, because it meant I couldn’t actually build anything for six months.”

Those six months proved pivotal to his journey, however. It gave him an extended window to tinker with his design, which was eventually supercharged by the discovery of the aforementioned second piece of media.

10. Blend It Like Boeing

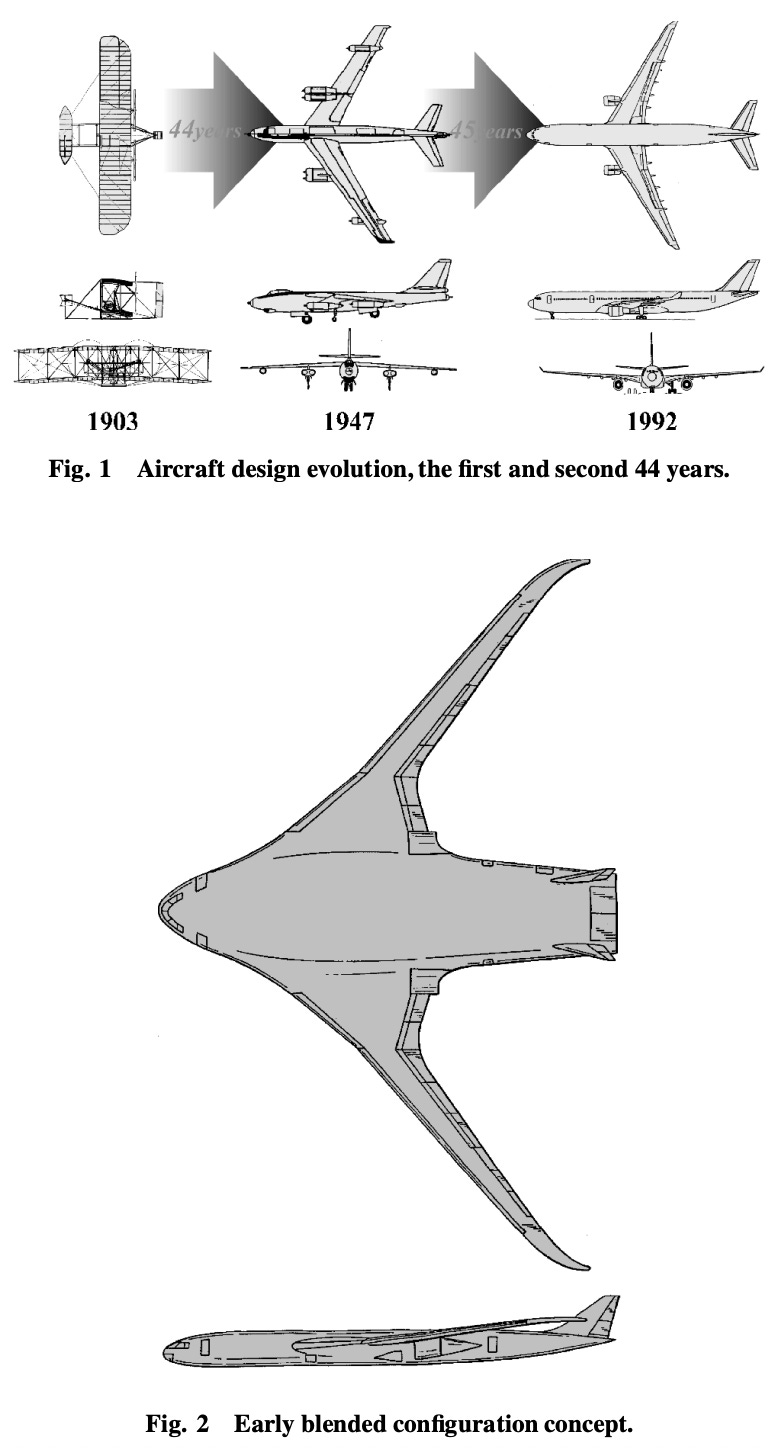

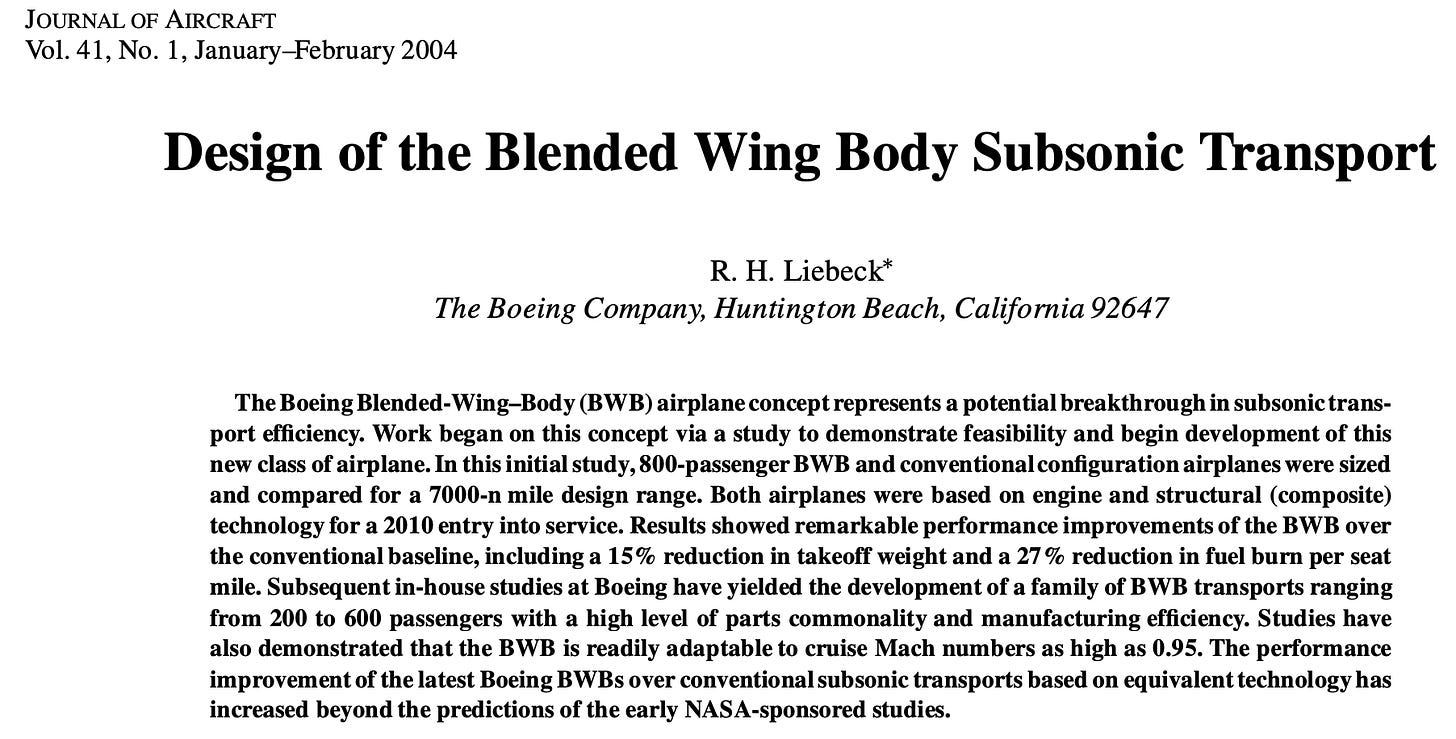

At an aerospace conference in 2004, Boeing engineers presented a wild new concept for an aircraft that looked like it came straight out of a sci-fi movie.

Instead of the familiar tube-with-wings-stuck-on design we’re used to seeing in commercial airplanes, their vision featured an aircraft with no clear line between the wings and the body. This “blended-wing-body” aircraft looked as if somebody had taken the model of a regular plane and sat on it by mistake.

The concept wasn’t entirely new. Engineers at (former defence and aerospace giant) McDonnell Douglas had been tinkering with the idea since the late 1990s. However, Boeing’s presentation marked the first time anyone had seriously proposed building these weird-looking planes for real-world use.

The genesis of the idea was that Boeing felt traditional aircraft design was fundamentally inefficient: you’ve got this big cylindrical fuselage (i.e. the main body of the plane which houses the cockpit, passengers, cargo etc) that just creates drag, while only the wings actually generate lift. What if, they wondered, the entire aircraft could generate lift? What if there was no dividing line between wing and body—just one smooth, aerodynamic shape?

What they envisioned was an aircraft that worked like a single airfoil. As you can see below, the result looked nothing like any plane that had ever flown previously, but the math was compelling: this strange design could potentially be 20-30% more fuel efficient than conventional aircraft and it could result in a 15-23% higher lift-to-drag ratio than a traditional tube-and-wing airplanes, amongst several other optimisation benefits.

Despite two decades of promising research and successful test flights with Boeing’s X-48 program, the blended wing body concept remained largely confined to experimental prototypes and niche military applications due to practical challenges like passenger evacuation concerns, airport infrastructure compatibility, and the massive costs of certifying such a radically different aircraft design. Though that didn’t deter a certain high-schooler from Mumbai from thinking that he could crack the code.

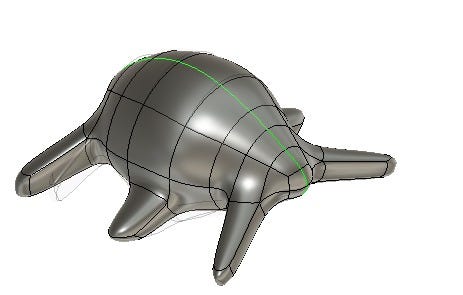

While Naman was waiting for the hackathon organisers to figure out how to transfer him his prize money, he stumbled upon Boeing’s original 2004 paper on the Blended Wing Body architecture. To his amateur aviation sensibilities - and because he literally didn’t know that it was too impractical to implement - it appeared to be the final piece of his design puzzle.

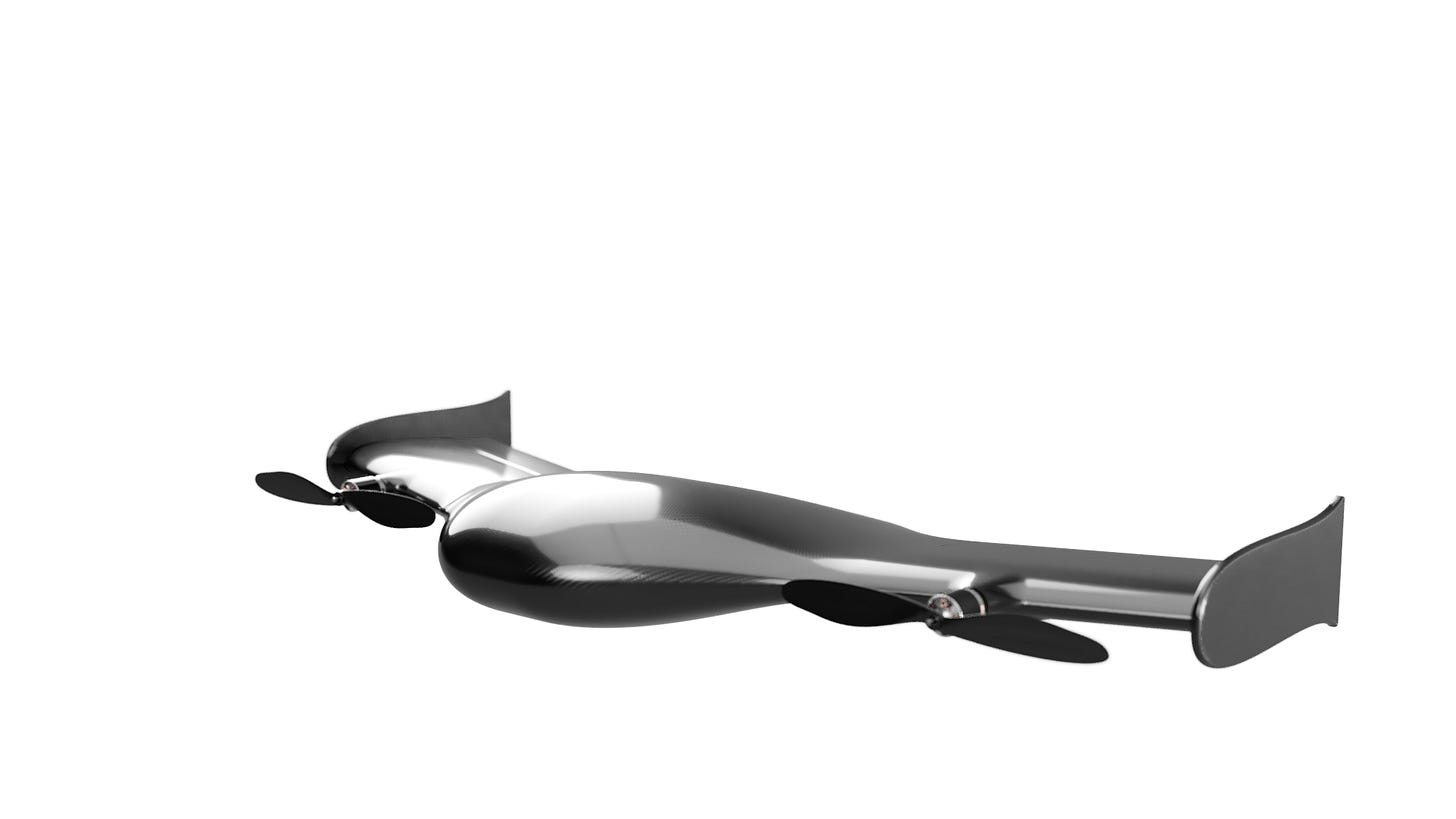

“The big problem with hobby-drone type tailsitters is that they’re not built to carry anything,” Naman explains. “They’re effectively just flying wings with a chunky redundant fuselage in the middle. A blended wing body essentially turns this fuselage into an airfoil - there’s no point where the wing ends and the fuselage (body) begins, so the entire thing is generating lift. So for instance, while your typical quadplanes have a lift-to-drag ratio of 3 to 3.5 at most, and airliners are at 17 to 20, a blended wing body offers 24 and up. The design is roughly 20% more aerodynamically efficient than existing tube-and-wing planes. That type of performance compounds in an incredibly positive way. A better lift-to-drag ratio means I use less energy to fly the same distance, which means I need a smaller battery. A smaller battery means less weight to carry, which means I can use smaller motors, which means less weight and even better efficiency - i.e. a positive feedback loop.”

“Equally important [seen in the image above], the fuselage can be designed to be thicker, to also store cargo. So it’s an airfoil that doubles as a storage compartment for a payload. This sort of overturns the disadvantages of a tailsitter, which, isn’t really aerodynamically efficient or equipped to carry things. When you combine a Blended Wing design with a tailsitter’s VTOL capabilities, suddenly you’re 5-6Xing your range and payload-carrying capability compared with any other drone ever. Why wouldn’t you try to do that?”

So, to summarise, Naman took what was an unproven, sketchy solution to the ‘VTOL Problem’ (re: combining vertical take off and landing ability with the efficiency of fixed wing flight), and paired it with an unproven, impractical aircraft configuration, smooshing them together to design what was (and is) the world’s only Blended Wing Body Tailsitter. Simple.

The only thing left to do was to build it.

11. What are you made of?

After six months of tweaking the renderings of his design, Naman spent the following six months learning what it took to build a drone that worked (…with dubious end results, but we’re getting ahead of ourselves). This was especially important to get right because $500 isn’t a lot when you need to account for the structure of a drone, the wiring, the motors, the propellers, the batteries etc.

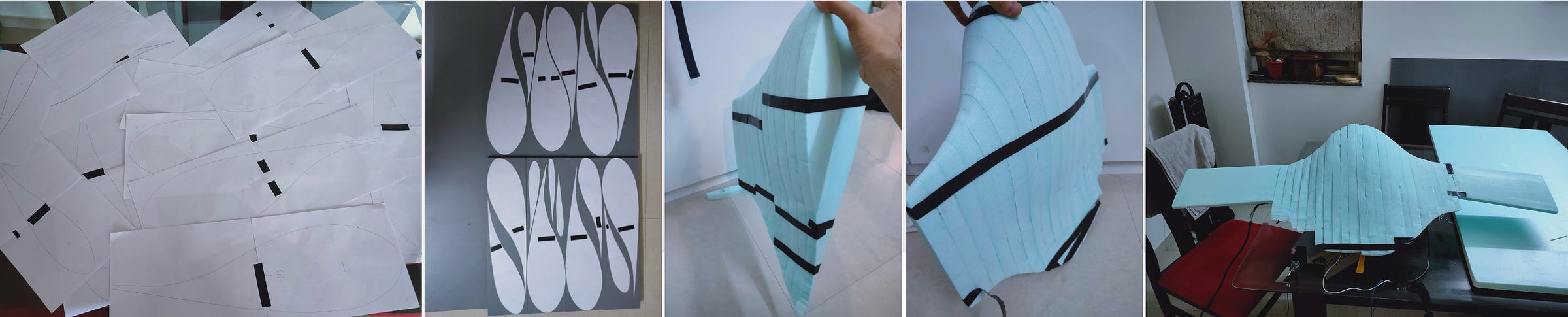

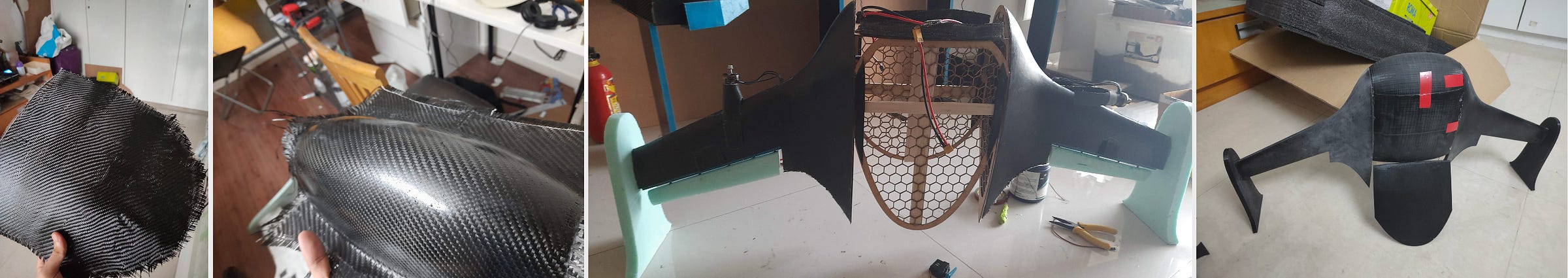

“I had to be insanely scrappy,” he recalls. “I didn’t know anything about aerodynamic principles then. I was just playing around with a bunch of random airfoil designs and seeing what came together. It was more of a 3D modelling exercise than an aerodynamic challenge. Things became trickier because I couldn’t afford an actual 3D printer. So I printed out the stencils of each part using a regular A4 paper printer, and then used a hot-wire cutter to carve the actual parts out of industrial foam. Then I basically stuck them together with toothpicks and tape and some adhesive. I added some polyester putty to fill in any gaps, and then sanded down till I got a smooth shape.”

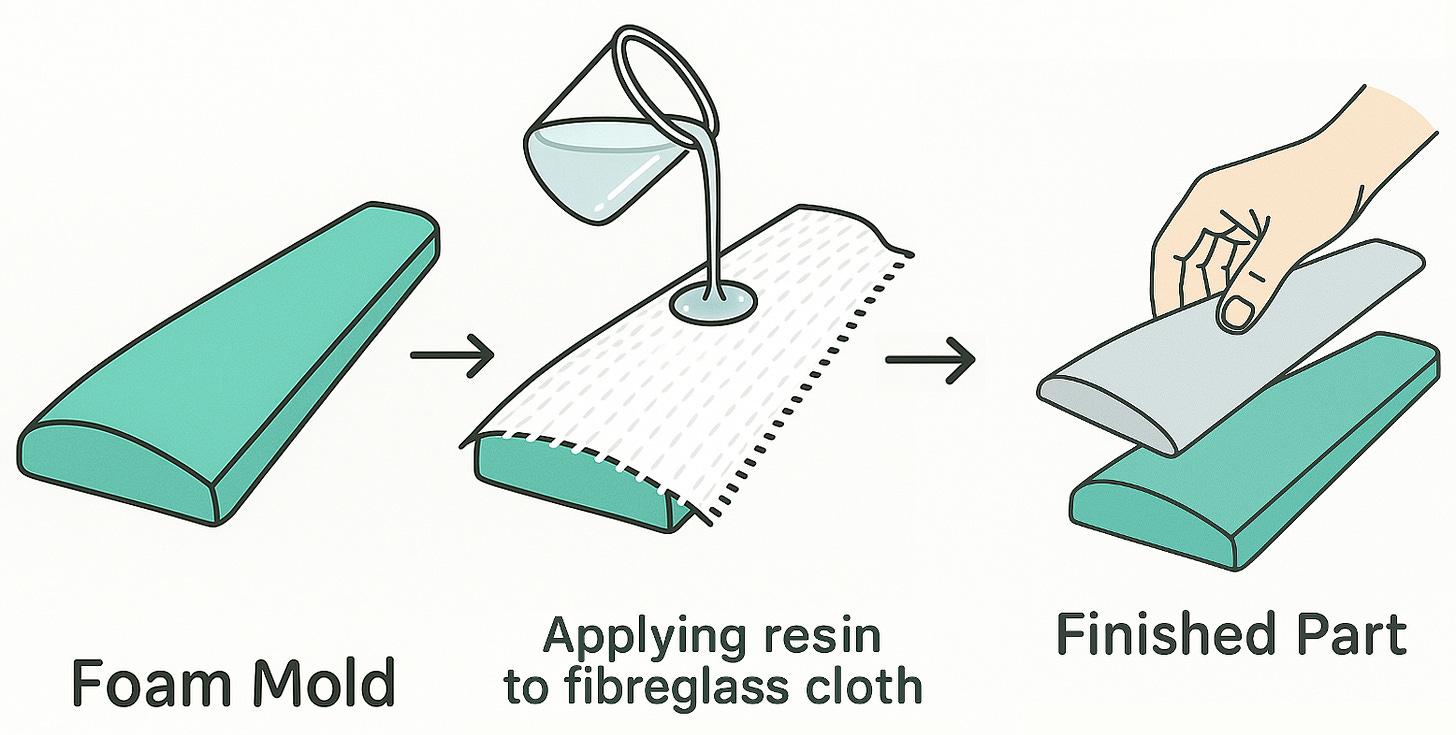

Now to clear up any misconception, the foam model you’re looking at in the images above isn’t the actual drone. That’s just the mould that Naman used to make the real frame of the drone. Naman’s actual drone prototype was made out of fibreglass, a type of composite material.

The process of making a fibreglass drone starts with making a mould of the entire drone out of foam as per the images you see. The idea is to then lay sheets of fibreglass (which are literally pieces of cloth) over different individual sections of this mould (i.e. different parts of the drone), then applying to these some type of liquid resin that reacts with the material, turning that soft cloth into a hard shell.

Then you would remove (i.e. peel off) those dried parts from the mould later on, before constructing the real drone out of your finished (hardened) fibreglass parts.

If you read through those last few sentences and said ‘WTF does that mean??’ in your head multiple times, don’t worry. I’ve been through the same process over the past four months. It’s probably worthwhile here to spend a couple of paragraphs talking about composite-making because it’s a big reason why Airbound is Airbound (and it’s also the last bit of technical exposition you need to make it through the rest of this piece, I promise). We’ll do this quick and dirty so we can return to our story.

For starters, what are drones made of?

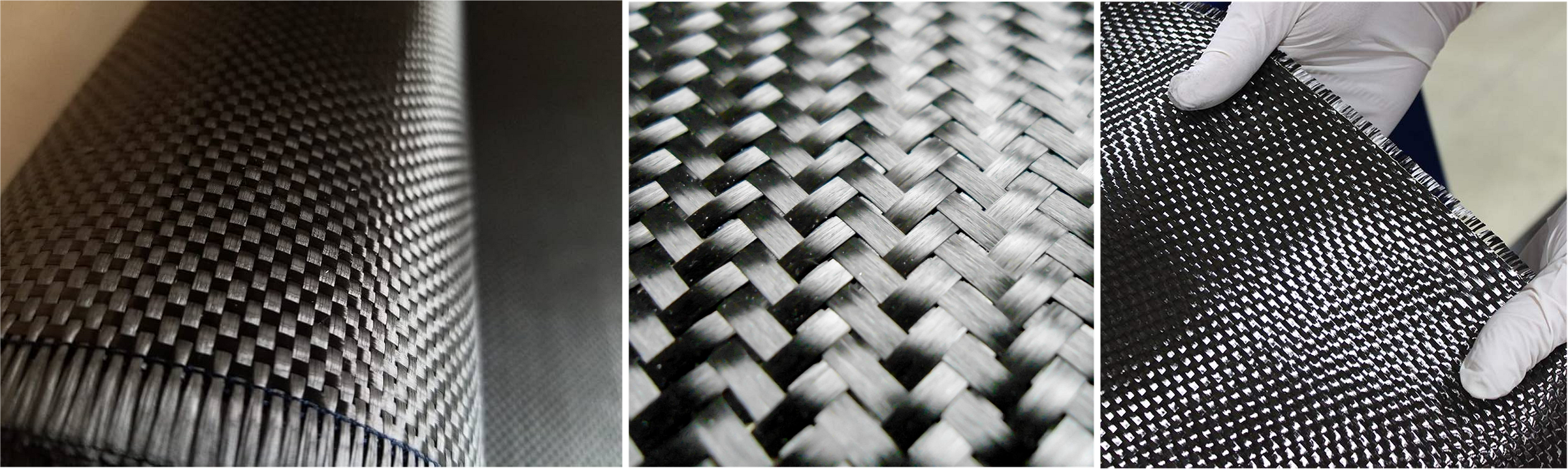

Drones, like cars, make use of different materials based on what each component needs to accomplish. Consumer drones use plastic bodies (cheap and easy to mould) with carbon fibre wings (strong enough to handle propeller stress), while commercial drones increasingly use composite materials like carbon fibre, kevlar and fibreglass for maximum weight savings. The fundamental challenge is building something strong enough to not fall apart mid-flight, but light enough that you’re not wasting energy carrying the aircraft’s own weight. Carbon fibre offers the best strength-to-weight ratio, which directly translates to longer flight times and bigger payloads.

Wait but what the hell are composites?

Composites are materials made by combining two different substances to get properties that neither has alone. Think reinforced concrete: concrete is strong under compression but cracks easily under tension, so engineers add steel bars to handle the tension forces; fibreglass boats work the same way - glass fibres provide strength while plastic resin holds everything together and makes it waterproof; or kevlar where synthetic polymer fibres combine with resin to absorb impact that would shatter either material alone. Each of these combinations work better than the constituent materials by themselves.

Cool cool cool. You said commercial drones tend to use fibreglass, carbon fibre and kevlar, right? What’s great about them (aside from being terms everyone pretends to understand)?

All three are essentially high-tech fabrics (literally cloth) that become incredibly strong when you add a liquid plastic resin (like epoxy) to them.

Fibreglass starts as molten glass stretched into threads finer than hair, then woven into cloth. Soak that glass cloth in resin, let it harden, and you get the material used for boat hulls and car parts.

Carbon fibre works the same way but uses carbon atoms arranged into ultra-thin strands instead of glass. The result is lighter than aluminium but stronger than steel—which is why it’s the go-to material for Formula 1 cars and spacecraft.

Kevlar uses synthetic polymer fibres that are designed to stretch and absorb impact without breaking, making it perfect for bulletproof vests and protective gear.

The key insight is directional control: you can orient these fibres in specific patterns to handle the exact forces your part will face - lengthwise for pulling forces, at angles for twisting, and so on.

This is why carbon fibre is the holy grail for aircraft builders (airplanes, drones etc) — you can engineer strength exactly where you need it without adding unnecessary weight elsewhere.

And how do you make things out of carbon fibre?

The basic process is surprisingly hands-on. You start by making a mould of whatever shape you want—this could be carved foam like Naman used, or made out of fibreglass itself, or some more sophisticated tool for mass production.

Then you ‘lay’ the dry carbon fibre fabric (this works even for fibreglass cloth) over the mould, making sure it follows all the curves and contours. Next comes the resin application: you either brush liquid epoxy directly onto the fabric or use a vacuum to suck the resin through the fibres. The idea is to get the resin to fully saturate the fabric without air bubbles, which would create weak spots.

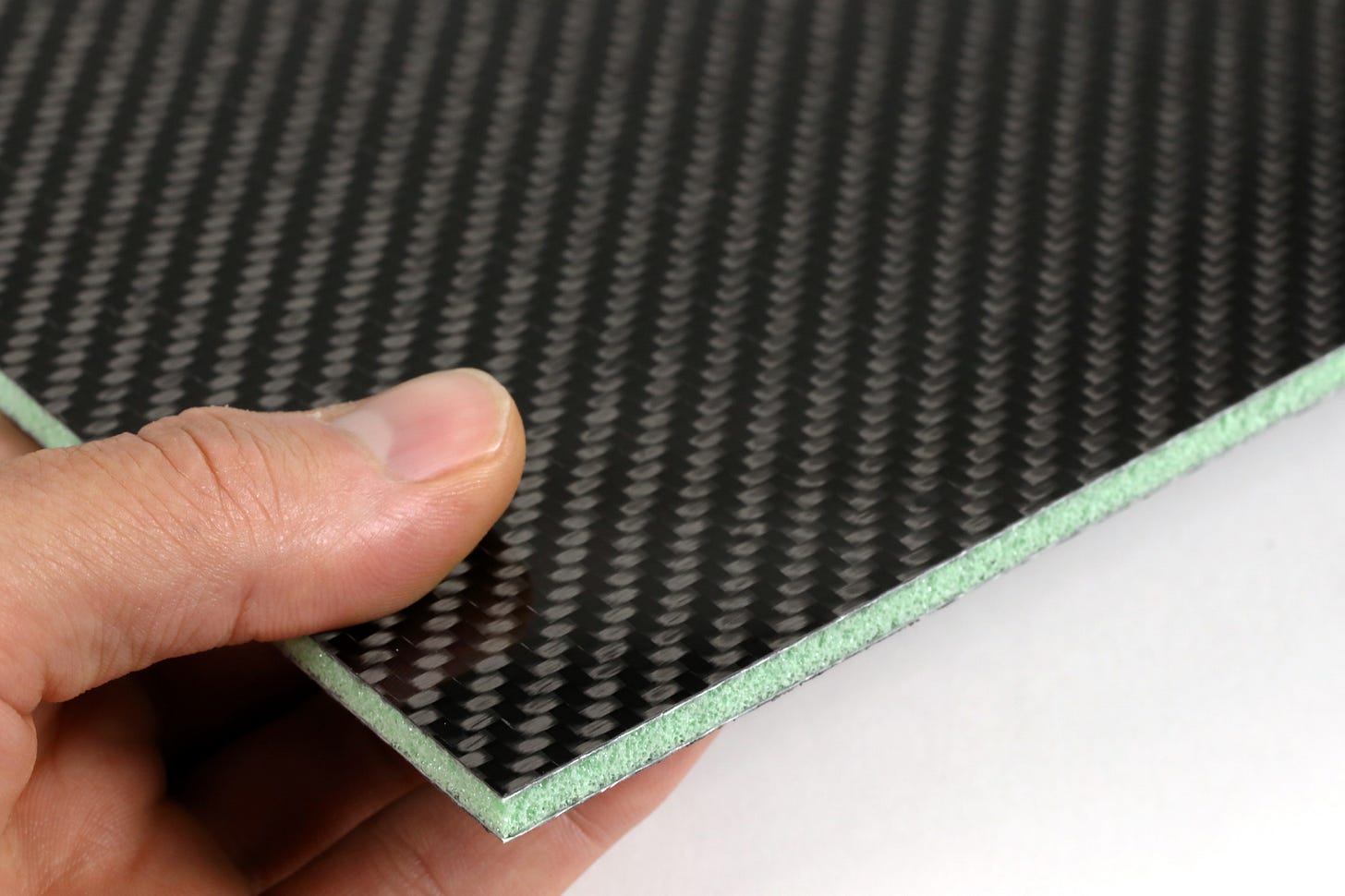

Once the resin cures (hardens), you remove the finished part from the mould. The result is an incredibly strong but lightweight shell. For complex parts like aircraft fuselages, you might need to join multiple pieces together with more resin and fibre reinforcement at the seams, or with mechanical fasteners for larger applications. For additional stability, it’s common to sandwich a lightweight foam core between two layers of carbon fibre—this provides the structural stiffness of much thicker solid material without the weight penalty, creating what’s literally called a sandwich panel.

Carbon fibre work requires some skill—too little resin and the part will be weak, too much and you’re adding unnecessary weight. The curing time depends on temperature and humidity, and professional operations use ovens or autoclaves to control these conditions precisely.

Professional grade operations rely on a ton of sophistication to balance quality and scale, but the basic technique is accessible enough that an enthusiastic high schooler could learn it in his bedroom with relatively simple tools.

12. Flight Time

“…So how are you going to do this? Instead of doing the logical thing and going for composites, your genius brain decided, you know what the best material for this insanely complex 3D curvature that’s incredibly sensitive to any changes in shape? Aluminum. Jesus christ, that was a month that could have been better spent doing literally anything else. Well now that you’ve finally knocked some sense into yourself and decided to build it out of fiberglass – and look at that, you’re making the mold out of foam too! I mean you made that little error where you bought 20 human sized sheets of PVC foam instead of XPS foam (I’m honestly impressed that you managed to fuck that up) but hey I’ll be nice and ignore that.”

- via Naman’s Substack (~early 2021)

Beyond tackling the art and craft of foam-cutting and fibreglass-moulding, Naman had to wrangle with the electronics, wiring and software that transforms a drone-shaped sculpture into something that actually flies. He relied on trusted mentors AKA Messrs Youtube, Google and Github, along with reaching out to college kids doing drone competitions and pestering them for advice.

“I did everything wrong basically,” Naman admits. “Like I hadn’t left any space in my frame to actually mount the motors. I had to refit the frame to get my angles right. Even the surface of the drone looked kind of…pixelated. Then I couldn’t get any of the open source drone softwares to work. I didn’t know anything about stability or controls or any of that stuff. I realised all my dimensions were wrong. By the end I think I developed a pathological fear of propellers because of how many times I messed up the sizing.”

If the first six months of Naman’s quest represented an exercise in imagination, the next six were a dogged return to reality. Slowly, addressing each of the practical challenges of drone making, his initial prototype came together, taking shape over the first half of 2021.

Considering that this was the handiwork of a 15-year-old in his bedroom with no experience in aerodynamics or aviation or composites, the resultant drone was reasonably handsome. But when it finally came down to showtime, the performance of the aircraft fell short of Naman’s own expectations.

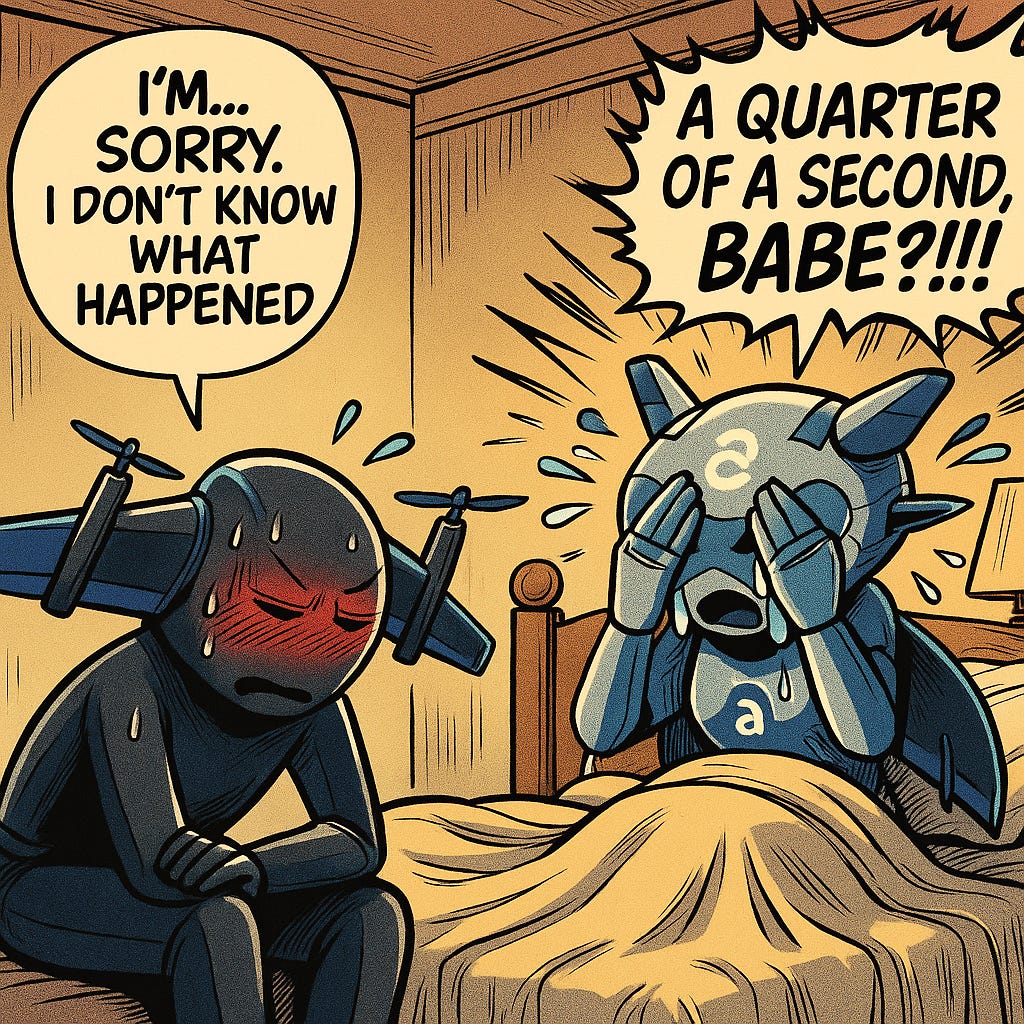

“I had underestimated the amount of thrust I needed to get it off the ground to actually fly. Plus I couldn’t get the software to behave properly. So when I finally tried to launch it, it lasted only 0.2 seconds of flight time, which was really disappointing.”

The benefit of getting everything wrong the first time around is that you get a lot of mistakes out of the way early. The other benefit is that you generate evidence of your intent.

Naman’s unsuccessful flight video (filmed by his mom) might not have depicted a satisfying climax…

…but it proved invaluable as an accomplice to various applications for grants and other sources of funding. He managed to win $1,000 as a grant from 1517 Fund (backed by Peter Thiel), which allowed him to finally buy a 3D printer to quicken the process of making foam moulds, and the subsequent carbon fibre parts. This was followed up by a larger grant from Emergent Ventures ($12,000), and pivotally, his first round of venture funding while he was still in the 11th grade, from a fund that was cut from the same cloth as he was.

13. Good Company

Abhishek Sethi and Prateek Behera founded gradCapital in 2021 while the former was still a postgrad college student at IIM Ahmedabad. The two had initially become friends as part of the 2018 graduating class at BITS Pilani. Their thesis for gradCapital was to focus on investing in startups founded by students, with a strong emphasis on ambitious technical and science projects in their early stages.

The duo have earned a reputation as some of the finest talent spotters in the country, having now invested early in companies like Stimuler, Armatrix, Arctus Aerospace, Pluto Mobility, and others. They kickstarted their first fund in 2021 via a programme that invited applications from student founders across the country, offering a standard $25,000 cheque in exchange for 4% equity in companies that made it through. One of the student founders that applied was Naman Pushp.

“At that time it was still a side-project, not a company,” Abhishek recounted over a call with me. “We were happy to fund side-projects though. For Naman it was initially just a technology play, but what became apparent to us over subsequent conversations was his belief that he’d effectively engineered a new cost structure for the movement of goods, that his aircraft would make drone delivery economically viable because a lighter, more aerodynamic frame meant a dramatic lowering of energy consumption costs. It’s almost like, if you can make last mile delivery effectively free - which is what he’s now estimating at scale - the movement of goods increases in all sorts of interesting and unpredictable ways. It’s like what the Internet did for data, or UPI did for money, they want to do for the physical world — for the world of atoms. Drones just happen to be the form factor.”

Abhishek also added that “What sealed it for us was that every time we would meet over a call, he would be sanding his drone for the entirety of the conversation, because he couldn’t find any other time to do so along with his schoolwork. His parents couldn’t believe it when we told them we wanted to fund him. They hadn’t realised there was something real here. In their heads he was eventually going to leave this hobby project aside when he went to college.”

Not only did the gradCapital guys give Naman $25K, but they also wrote his college recommendation letter. As to why a new venture fund that had just committed $25K to a founder would want to boost his chances of abandoning his nascent venture in favour of beer pong and bong hits (and a classroom education, I guess), the reasoning was simple “His parents were keen that he apply to college, so we wanted to help give them some comfort,” says Abhishek. “But to us, we saw a kid that was so obsessed with this idea that he wouldn’t even take a break from sanding his drone during an interview to raise funding. That kind of obsession will always pull you back to your mission.”

And so it did for Naman, who knew by the end of his 11th grade that he wasn’t going to go to university. It was a decision that gave his parents much stress, and not one they were immediately on board with. “They were worried about me and wanted me to have a safety net,” says Naman. “My dad comes from a humble background where, in his family, being an entrepreneur just meant you couldn’t get a good job somewhere else. He had seen the business owners around him struggle when markets turned for the worse. He never wanted me to go through that. But I knew I wanted to see what this could become. I don’t think you can build a meaningful company if you’re also trying to get through college.”

What helped his cause was raising his first round of funding from gradCapital (which along with the other grant money gave him $40K to play with as he transitioned from the 11th to the 12th grade), and then raising another ‘extender’ round of ~$150K from Draper Startup House and other angels while in his last year of high school. To meet his parents halfway, he applied for college anyway. “I got into Carnegie Mellon,” he says. “The good part of university in America is that you can defer your admission, which I did for two years, so my parents could be satisfied that I had a back up. Though as of last year I think I’ve had to give up my seat.”

Over his final year of school, the project formerly known as OpenDrone came of age, emerging from puberty as a plucky venture-funded company with grand ambitions to move the world.

14. Airbound

Naman freely admits that his commitment to academia took a dive in the last year of high school. Apart from the requirements of running a real company - now called Airbound - in his after school hours, his faith in the efficacy of classroom education had been fundamentally shaken.

“I had always grown up wanting to do something big, something bold,” he reflects, “and I knew that technology was what allowed you to scale good ideas to make the biggest impact. But before COVID I had always assumed that academics was the only path to get there. I was the kid that wanted to get a pHd. But after exploring this world of drones and aviation and robotics on my own, and finding people that were willing to bet on me on the back of that work, that broke all my earlier assumptions. Like, I used to think that an engineer was someone with an engineering degree, but I realised over that period that an engineer is just someone who does engineering.”

For Naman, that ethos became especially pronounced while breaking new ground. “If you’re building something that’s never been built before, you’re probably not going to find your answers in some lecture or college textbook. Conversely, if you’re obsessed, and if you eat, breathe, and sleep thinking about the problem, that’s when answers tend to reveal themselves.”

After the gradCapital round, Naman moved into his own apartment, which became the unofficial Airbound lab. He tried to convince his parents to let him move to Bangalore since school was online for the foreseeable future. “But they weren’t having it,” he recalls.

The priority for his new company was simply to build a drone that worked. That meant several months going deep into each element - hardware, software and electronics. It meant reworking the design for his prototype from scratch, understanding the complex dance of control surfaces and sensors that help to keep an aircraft stable in the air and direct its movements. He also upgraded to using carbon fibre and kevlar sheets instead of fibreglass, for better strength-to-weight optimisation and greater impact absorption, respectively.

This time, he allowed his efforts to be directed by a primary use case - i.e. the delivery of medicines, in keeping with the theme of his original mission to find a solution for contactless delivery.

It meant researching the weight of a typical medical delivery (of which a majority fall under 1 kg), and following that throughline to design a fuselage that could accommodate such a payload → then visualising the shape of an airfoil that could surround it → estimating the kind of thrust needed to lift such an aircraft → and how many batteries of a certain type that would require → and how much weight those batteries would add → and how much weight his frame would need to be to make it all work, and so on.

“At first this was all just about CapEx,” Naman says. “All I was initially trying to do was figure out zero-infrastructure drone delivery, because that’s the only way I thought this could scale. But gradually over the next 12-18 months it turned into an optimisation game, and suddenly I was looking at all these figures for payload-to-weight, strength-to-weight, cost-per-kilometre etc. I wasn’t really chasing any benchmarks. I just started with the basic physics of designing the most efficient delivery drone I thought could exist, and let that be my guide.” Naman’s exploration of different rabbit holes unearthed a number of questions that would form the basis for his eventual aircraft design - basic questions that only someone ignorant of convention would ask - like:

Why was it that when you looked at existing drones in the market, it was always a big object carrying a little object, and not the other way around? Why did all the existing delivery drones weigh between 4-8x more than the maximum payload they could carry?

Why is it that airplanes can carry so much more payload as a percentage of their weight than quadcopters or VTOL aircraft?

Why was drone delivery seen as a ‘compromise’ option today - high cost per kilometre in exchange for higher speed and more access? Why couldn’t it be all three? Why had drone companies begun dealing in tradeoffs before they’d found optimum performance on range, weight, cost, and performance? What was it that made them so inefficient today? What was holding them back?

How light could your frame be if you just used the lightest material available in the market, instead of the lightest material that everyone else was using?

If your goal was to make the lightest and most aerodynamic structure physically possible, how would that affect your energy requirement? What would that mean for the performance and life of your battery? What would that do for your cost per kilometre? And how would that compare with other modes of delivery transport?

As it is for most questions at Airbound, the proof is in the physics.

15. Lightspeed

Over the course of 2021 and 2022, Airbound’s V1 aircraft took shape, designed to carry a 1kg payload that covered most medical deliveries. It featured an ultra-lightweight carbon fibre frame that employed first-principles engineering to distribute strength and weight across the body of the drone. That meant looking at structures at a molecular level, and borrowing techniques from earthquake-resistant building architecture.

Because it’s very difficult to change the basic structure of an aircraft once it’s finalised - each tiny change has a cascading effect on everything else - this is largely the version that the company is still working off of today.

Along with better materials and components, Naman now had the funds to expand the Airbound team too. Chief amongst the early additions was Ganesh Yadav, the first official team member at Airbound who became (and still is) a key cog in the Airbound machine.